Steel grit with SAE standard specification

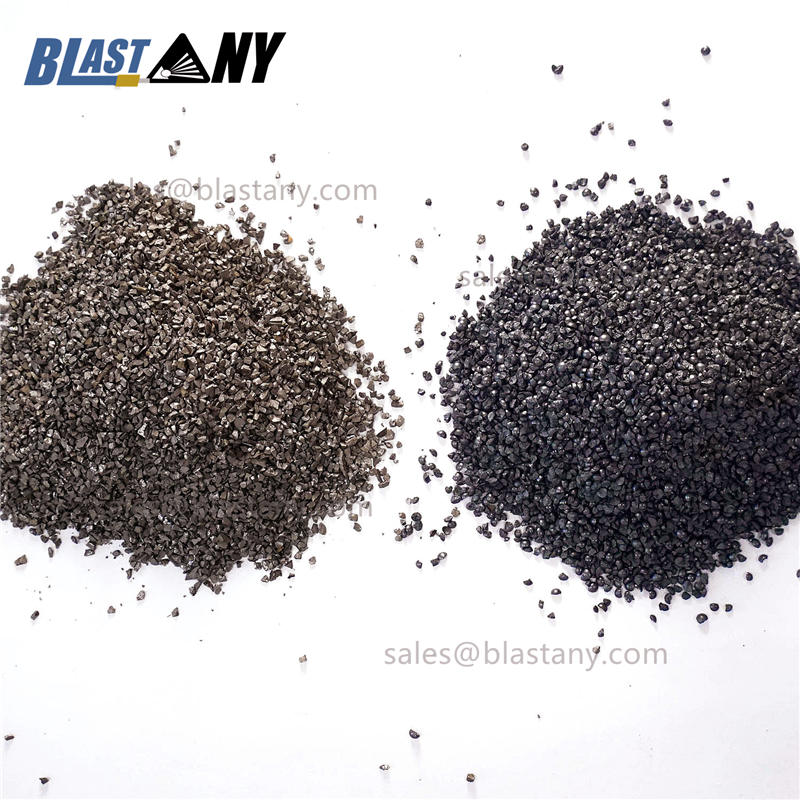

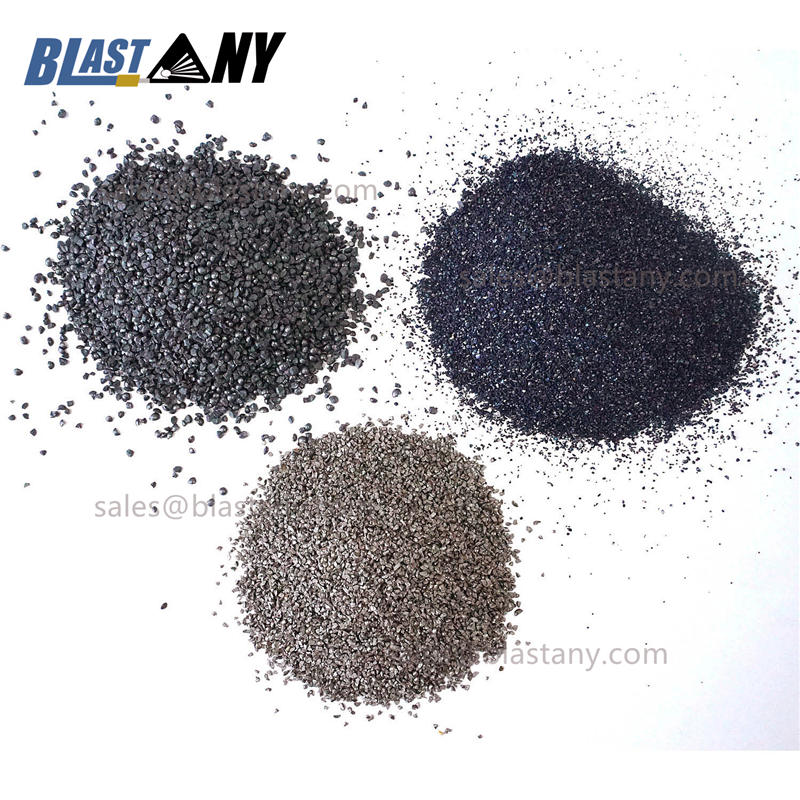

Junda Steel grit of different hardness

1. GP steel grit: This abrasive, when newly made, is pointed and ribbed, and its edges and corners are quickly rounded during use. It is especially suitable for the pretreatment of steel surface removal of oxide.

2. GL grit: Although the hardness of GL grit is higher than GP grit, it still loses its edges and corners during the sandblasting process and is especially suitable for the pretreatment of removing the oxide scale on the steel surface.

3. GH steel sand: This kind of steel sand has high hardness and will always maintain edges and corners in sandblasting operation, which is particularly effective for forming regular and hairy surfaces. When GH steel sand is used in shot peening machine operation, construction requirements should be considered in preference to price factors (such as roll treatment in cold rolling mill). This steel grit is mainly used in compressed air shot peening equipment.

Industrial application

Steel grit Cleaning

Steel shot and grit are used in cleaning applications for removal of loose material on metal surfaces. This type of cleaning is common in automotive industry (motor blocks, cylinder heads, etc.)

Steel grit Surface preparation

Surface preparation is as a series of operations including cleaning and physical modification of a surface. Steel shot and grit are used in surface preparation process for cleaning metal surfaces which are covered with mill scale, dirt, rust, or paint coatings and for physically modifying the metal surface such as creating roughness for better application of paint and coating. The steel shots are generally employed in shot blasting machines.

Steel grit Stone cutting

Steel grit is used in cutting hard stones, such as granite. The grit is used in large multi-blade frames which cut the blocks of granite into thin slices.

Steel grit Shot peening

Shot peening is the repeated striking of a metal surface by hard shot particles. These multiple impacts produce a deformation on the metal surface but also improve the durability of the metal part. The media used in this application is spherical rather than angular. The reason is that spherical shots are more resistant to the fracture which happens due to the striking impact.

Steel grit for Sand blasting

Carbon steel grit quality used for sand blasting body section directly affect the quality and comprehensive cost factor in terms of the sand blasting efficiency,girder coating, painting, kinetic energy and abrasive consumption. With the new coating protection performances standard (PSPC) release, there is a higher request to the piece wise sand blasting quality. Therefore, the cast Steel grit quality is very important in the sand blasting.

Angular shot for sandblasting Container

Spherical steel grit sand blasting on the container box body after it welds. Clean up the welded joint and at the same time to cause the box body surface to have certain roughness and increase anti-corrosion painting effect, in order to be able to work for a long time among the ships, the chassis, the freight vehicle and the railroad vehicles.Our steel grit price is reasonable.

Grit spherical for The wild electricity equipment sandblasting

The wild electricity product has the specific request for roughness and cleanliness of the surface treatment .After angular steel grit surface treatment, they must undergo kinds of weather changes outdoor for a long- time. So that, the grit spherical sand blast for surface is specially pivotal.

Technical Parameters

|

SAE |

Application |

|

G-12 |

Blasting/descaling medium-to-large cast steel, cast iron, forged pieces,steel plate and rubber adhered work pieces. |

|

G-18 |

Cutting/grinding stone; Blasting rubber adhered work pieces; |

|

G-50 |

Blasting/descaling steel wire, spanner, steel pipe before painting process; |

Production Steps

Raw material

Tempering

Screening

Package

Products categories

-

Phone

-

E-mail