OEM Customized Sandblast Nozzle - Sandblasting pot for professional sandblasting work – Junda

OEM Customized Sandblast Nozzle - Sandblasting pot for professional sandblasting work – Junda Detail:

Sandblasting machine application

Junda Sandblasting machine widely used in ships,Bridges, mining, machinery, oil pipelines, machine tools, railway,metallurgy, boiler, machinery manufacturing, port construction, water conservancy projects for surface derusting and descaleing. lt is the most widely used product of abrasive jet, and the sandblasting machine is generally divided into two categories: dry and wet.

Sand blasting machine Working principle

In order to ensure the correct and stable use of Junda machine, it is very important to understand the equipment in detail. The following is introduced on its working principle diagram.

There are dry and wet blasters. Dry sand blaster can be divided into suction type and road type. A complete dry suction blaster is generally composed of six systems: structural system, medium power system, pipeline system, dust removal system, control system and auxiliary system.

Dry suction sand blasting machine is powered by compressed air, through the high speed movement of air flow in the negative pressure formed in the spray gun, the abrasive through the sand pipe. Suction spray gun and through the nozzle injection, spraying to be processed surface to achieve the desired processing purpose.

Working principle of press-in dry sand blasting machine: it is powered by compressed air. Through the working pressure established by the compressed air in the pressure tank, the abrasive passes the sand valve, is pressed into the sand pipe and shot through the nozzle, and sprayed to the processed surface for the expected processing objectives.

Advantages

1. 16 years manufacture and export experience.

2. Exporting to all over the world, win high reputation among customers.

3. CE, ISO 9001 and Strict Production Guideline to guarantee the high quality

4. Factory near the Qingdao port, convenient for exporting.

5. 24 hours online service & free technical support.

6. Competitive Price .

7. Strong Research & Development technical team.

8. Various sandblasting machinery to meet all your needs at our factory.

9. Engineers are available to guide the installation and take care of other problems.

10. We offer OEM&ODM service to meet all your requirements.

Packaging & Delivery

1. Coils are wrapped by 8 steel bands.

2. Wrapped by waterproof cloth.

3. Wrapped by 8 steel strips.

4. With wood pallet.

5. According to customer’s requirements.

Technical Parameters

| Model | JD-600 D/W | JD-700D/W | JD-800D/W | JD-1000D/W |

| Diameter | 600mm | 700mm | 800mm | 1000mm |

| Color | Customers’ Requirements | Customers’ Requirements | Customers’ Requirements | Customers’ Requirements |

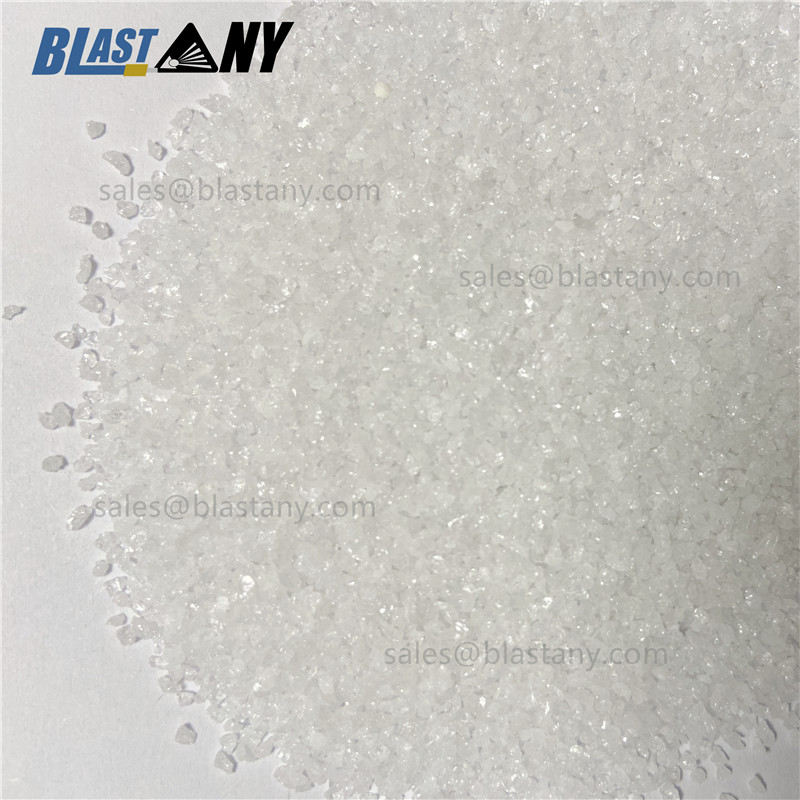

| Blasting Media | Abrasive | Abrasive | Abrasive | Abrasive |

| Height | 1450mm | 1650mm | 1800mm | 2000mm |

| Capacity | 0.3m³ | 0.4m³ | 0.6m³ | 1.0m³ |

| Efficiency | 5-10m²/h | 6-11m²/h | 10-12m²/h | 10-30m²/h |

| Pressure | 7Mpa | 7Mpa | 8Mpa | 8Mpa |

| Air Consumption | 3.6m³/min | 3.6m³/min | 3.6m³/min | 3.6m³/min |

Product detail pictures:

Related Product Guide:

We strive for excellence, services the customers, hopes to be the top cooperation team and dominator business for personnel, suppliers and prospects, realizes benefit share and continual promotion for OEM Customized Sandblast Nozzle - Sandblasting pot for professional sandblasting work – Junda , The product will supply to all over the world, such as: Portugal, Pakistan, luzern, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

Products categories