Grinding steel balls are the grinding media and the core components of a ball mill. They can directly affect the grinding efficiency of the whole ore processing plant and the final product quality.

During the grinding process, grinding steel balls are used for mixing and milling materials (such as minerals, paints, and chemicals) into fine powders.

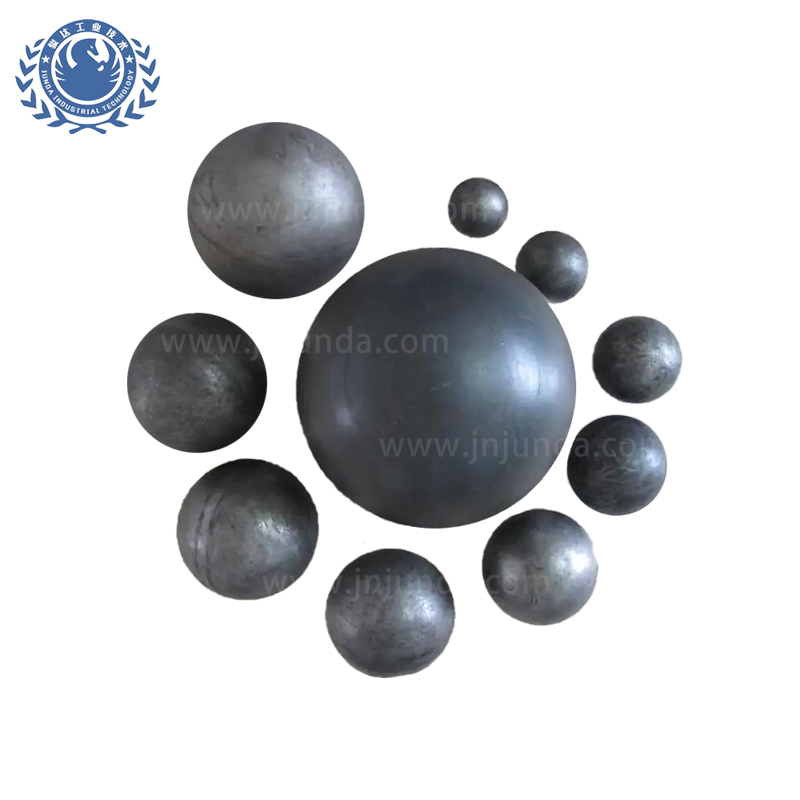

Types of grinding steel balls

As grinding steel balls need good abrasion resistance and enough impact toughness, and cannot be broken, Fote Machinery has done hardness test, chemical composition inspection and internal quality inspection for each ball.

According to the manufacturing process, ball mill steel balls for mining are divided into forged grinding steel balls and cast grinding steel balls.

1. Forged grinding steel balls

Want higher grinding efficiency? For gold mining or cement industry? Then you can choose forged grinding steel balls, which are available in all stages of milling.

Fote forged steel ball can be divided into low carbon, medium carbon, high carbon steel ball based on the carbon percentage.

The carbon content is below 1.0%. The chromium content is 0.1%-0.5% (Generally do not contain chromium).

2. Cast grinding steel balls

As another type of grinding media, cast grinding steel balls can provide Cr (1%-28%), hardness (HRC40-66), and Diameter (10mm-150mm) alloy cast steel balls.

They can be divided into low chromium, medium chromium, high chromium, super high chromium grinding ball (CR12%-28%).

Fote cast grinding steel balls has TWO STRENGTHS:

Low crushing ratio: The resistance to flaking and crushing is 10 times than that of other forged balls. The number of impacts of falling balls can reach more than100,000 times. The actual crushing rate is less than 0.5%, close to no crushing.

Good surface finish: The ball surface is not allowed to have casting defects, such as cracks, obvious pores, inclusions, shrinkage holes, cold insulation, elephant skin, etc.

Forged VS Cast grinding steel balls

Two types of grinding steel balls have different wear degree, as they are processed by Forged grinding steel ball: Water quenching is often used for forging steel balls, so its broken rate is high.

Cast grinding steel ball: It adopts high-temperature quenching and tempering treatment to make the grinding balls more tough and wear-resistant.

Therefore, the wear resistance comparison is shown below:

Cast grinding steel balls > forged grinding steel ball. And among the cast steel balls, high chromium ball > medium chromium ball > low chromium ball.

Post time: Jan-17-2024