1) Different raw materials.

The cast steel grit is made of scrap steel + alloy smelting; Bearing steel grit is bearing steel, with high and uniform hardness and wear resistance.

2) The production process is different.

The cast steel grit is made by smelting and casting, and has defects; Bearing steel grit is bearing steel direct quenching and heat treatment, no defects.

3) Metallic elements are different.

The main metals contained in the steel grit are :C, Mn, Si, S, P; Bearing steel grit contains the precious metal -Cr, it can enhance fatigue life and wear resistance.

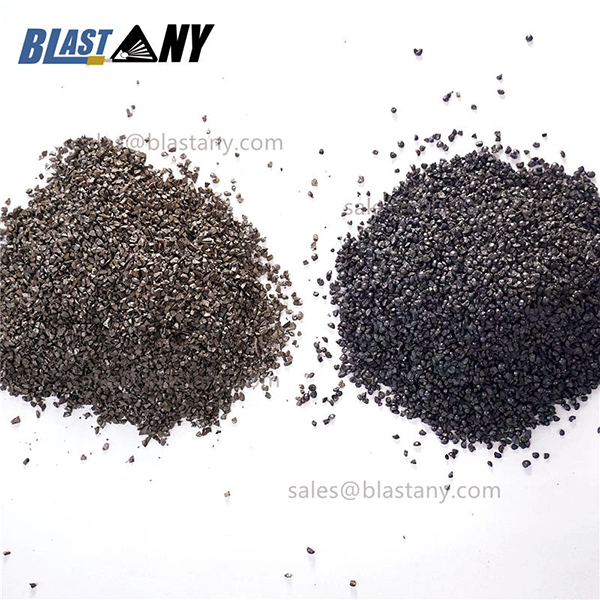

4) The appearance is different.

The surface of the cast steel grit is broken by the cast steel shot and has an arc shape;

Bearing steel grit is broken directly from bearing steel after quenching into grit, it is relatively sharp.

5) Different usage

Cast steel grit mainly used for sandblasting, grit blasting, Steel grit Cleaning, Surface preparation, Shot peening, Sand blasting

Bearing steel grit can used for sandblasting, rust removal, shot peening, shot blasting,

Because it’s high hardness, it can specially used for granite and stone cutting,

6) The price is different.

Cast steel grit is cheaper, bearing steel grit is expensive, the cost of raw materials is not the same. Bearing steel grit contains precious metal - chromium, through the unique production process, excellent metallographic structure, full product particles, uniform hardness, high cycle times, can effectively improve the recovery rate (abrasive in the process of sand blasting gradually reduced), so as to reduce the consumption rate of abrasive up to 30%.

Post time: Jun-21-2024