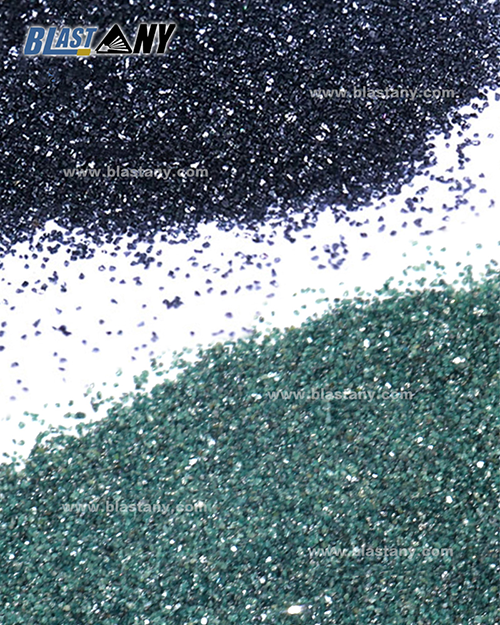

Do you know about black silicon carbide and green silicon carbide?

Key words: #siliconcarbide #silicon #Introduction #sandblasting

● Black silicon carbide:Junda Silicon Carbide Grit is the hardest blasting media available. This high-quality product is manufactured to a blocky, angular grain shape. This media will break down continuously resulting in sharp, cutting edges.The hardness of Silicon Carbide Grit allows for shorter blast times relative to softer medias.

● Silicon carbide has a very high hardness, with a Mohs hardness of 9.5, second only to the world's hardest diamond (10).It has excellent thermal conductivity, is a semiconductor, and can resist oxidation at high temperatures.

● Green silicon carbide:Green silicon carbide manufacturing method is the same as that of black silicon carbide, but the purity of the raw materials used requires a higher degree of purity, It also forms green,semi transparent,hexagonal crystal shapes at a high temperature of about 2200℃ in a resistance furnace. It’s Sic content is higher than that of black silicon and it’s properties are similar to black silicon carbide, but it’s performance is slightly more brittle than black silicon carbide.It also has a better thermal conductivity and semiconductor properties.

● Application:

1.Cutting and grinding of the solar wafers, semiconductor wafers, and quartz chips.

2.Polishing of crystal and pure grain iron.

3.Precision polishing and sandblasting of ceramics and special steel.

4.Cutting, free grinding and polishing of fixed and coated abrasive tools.

5.Grinding the non-metallic materials such as glass, stone, agate and high-grade jewellery jade.

6.Manufacturing the advanced refractory materials,engineering ceramics, heating elements and thermal energy elements, etc.

Post time: Aug-28-2024