Most bead blasting projects give dull finishes with probably a bit of satin shine added to them. However, these finishes are usually fairly poor. Glass bead blasting has become very popular in recent years. The restoration in its popularity is generally due to the benefits it offers in manufacturing.

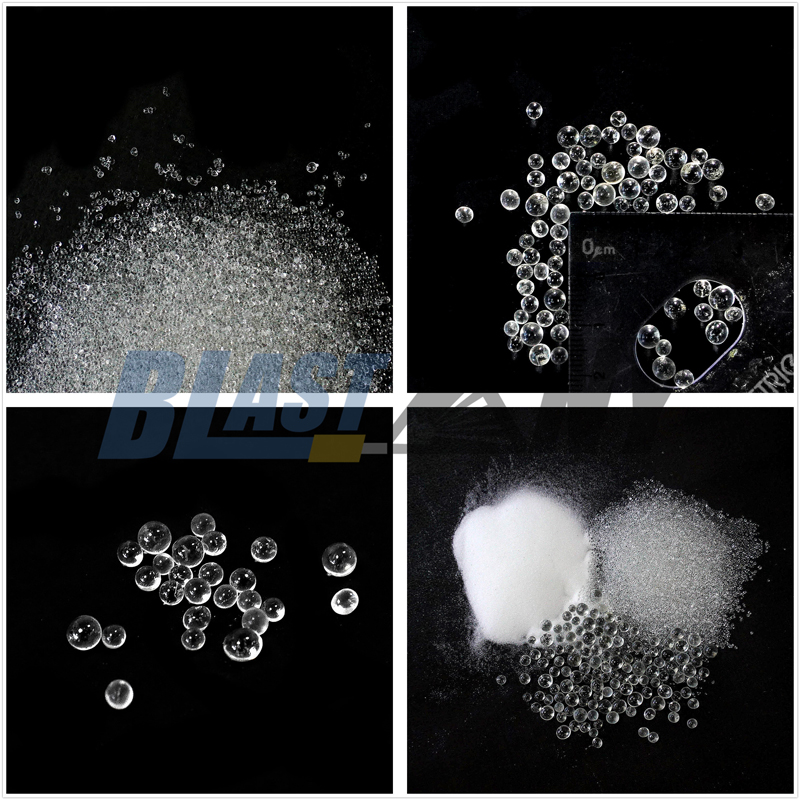

Unfortunately, many people only see glass beads as a way of restoring parts. They use these beads to clean off rusts, dirt, scale, etc. At the same time, the beads are expected to leave excellent bead blast finishes. Without much said, let’s examine some tips to help you get the best bead blast finish.

Use low pressure for bead blasting

The first tip is to turn down the pressure of your bead blaster, with 50 PSI (3.5 Bar) usually a good point to start. You must note that glass beads work best at low pressures. Therefore, the pressure should be as low as possible. This way, you can increase how long your beads stay and get a much better metal surface finishing.

50 PSI pressure with a siphon blaster will help get the optimum result. The design of glass beads does not allow them to be cut. Instead, they are made to polish or burnish a part. However, they do this at higher rates than other tumbling media. When you turn their pressure up, the beads begin to smash on impact with the component. This way, you crush the beads and incur higher processing costs.

Furthermore, smashing glass beads into your parts at high pressure produces excess dust, debris, and sharp particles. These particles trap inside the cabinet and would affect the remaining clean beads. Contamination is bound to happen this way, leading to degraded finishes. With higher pressures on beads at impact, a lot of the smashed particles embeds on the component’s surface. Therefore, you don’t want to use high-pressure bead blasting on internal engine parts or other critical components.

Strip off any rusts or oxides before bead blasting

There is no way to out a great bead blast finish on aluminum without first stripping off its oxide layer. The oxide layer is usually too hard to polish or burnish. Also, it may make it hard for stains to remove. Although there may be some shine to it, it will look like some shine stains. Note that glass bids will not help you strip off or get rid of the oxide layer. This is because their design does not allow them to cut.

Instead, it will help to use a sharp cutting abrasive to strip off the oxide or rust. Black beauty aluminum oxide, crushed glass, etc., will help you strip off rusts and oxides. The crushed glass is a preferred option because it is a fast process, similar to silicon carbide or aluminum oxide. It is also very clean, leaving a nice brighter finish on metals. Regardless of your choice of abrasive for stripping off oxides, a material with consistency is perfect. Some coarse braces with an abrasive will easily help you take off heavier scales.

Post time: Jul-01-2022