Key words: garnet sand#waterjet cutting#advantages#abrasives

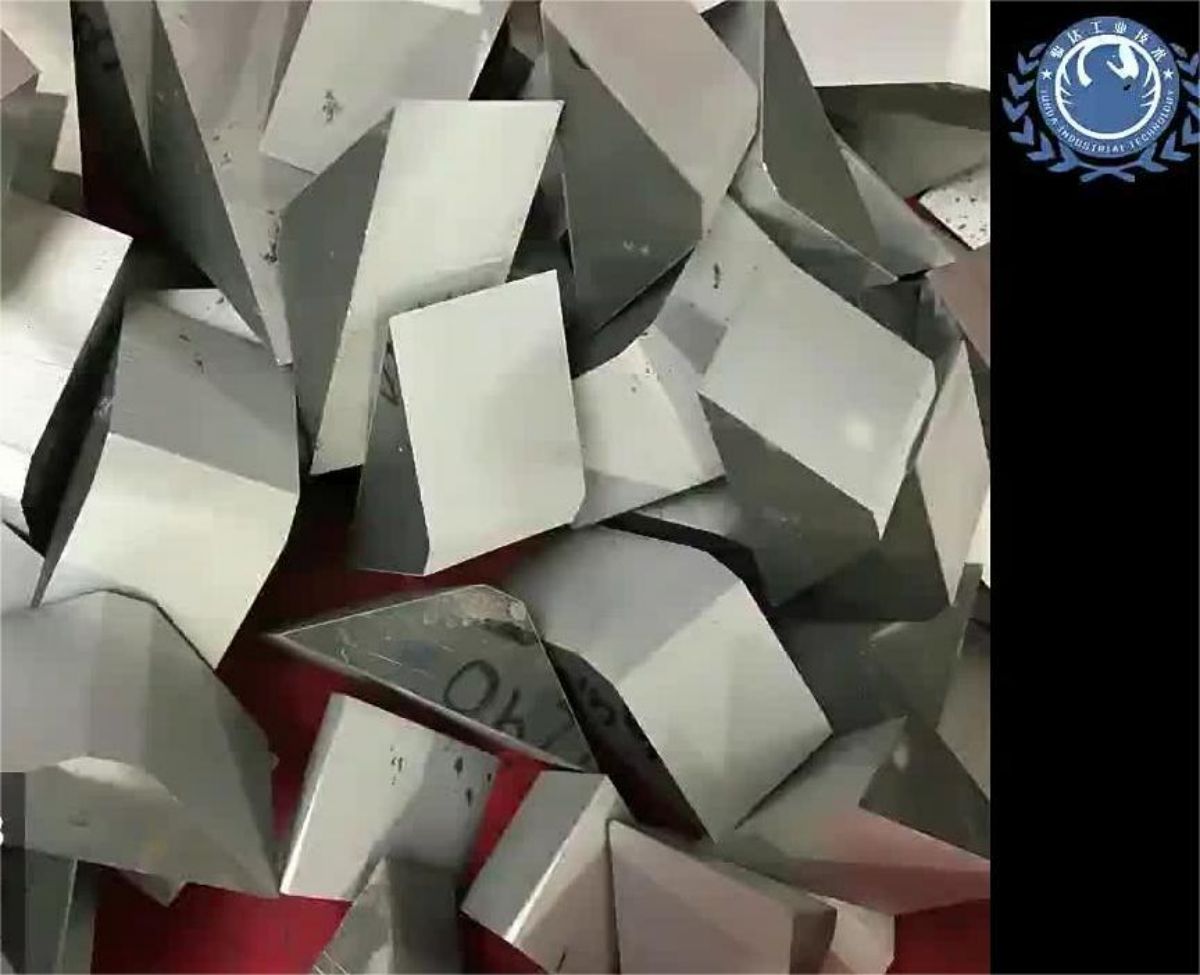

Garnet sand is currently widely used in the field of waterjet. The application of garnet sand makes waterjet cutting more perfect and efficient. This is also the reason why waterjet cutting stands out among many cutting methods, and it is now used very highly in industry and is used in more and more fields. The applicable materials are very wide. Whether in daily life or aerospace, many places require garnet sand for water cutting.

There are so many sandblasting abrasives on the market, why are garnet sandblasting abrasives widely used? This is determined by the excellent characteristics of garnet sand. It can combine cutting and precision processing, can cut any complex curves and graphics, and is very convenient to operate. Our Garnet 80 is very popular in the market.

Advantages:

1. Fast cutting speed

2. The cutting surface is smoother and straighter

3. There are no large particles blocking the sand pipe (nozzle)

4.No invalid fine particles of garnet, and dust

For waterjet cutting with garnet,we recommend the appropriate size and type of garnet.

Normally Rock garnet sand 80#A+ is recommended for cutting steel plate below 20mm, and rock garnet sand 80#H is recommended from 25 to 50#mm, river sand and sea sand are cleaner.Garnet 80H is the most commonly used and popular abrasive for cutting stones, marble, and ceramic tiles..

Post time: Mar-29-2024