Hot Sale For 35mm Stainless Steel Ball - Grinding ball – Junda

Hot Sale For 35mm Stainless Steel Ball - Grinding ball – Junda Detail:

Producing process

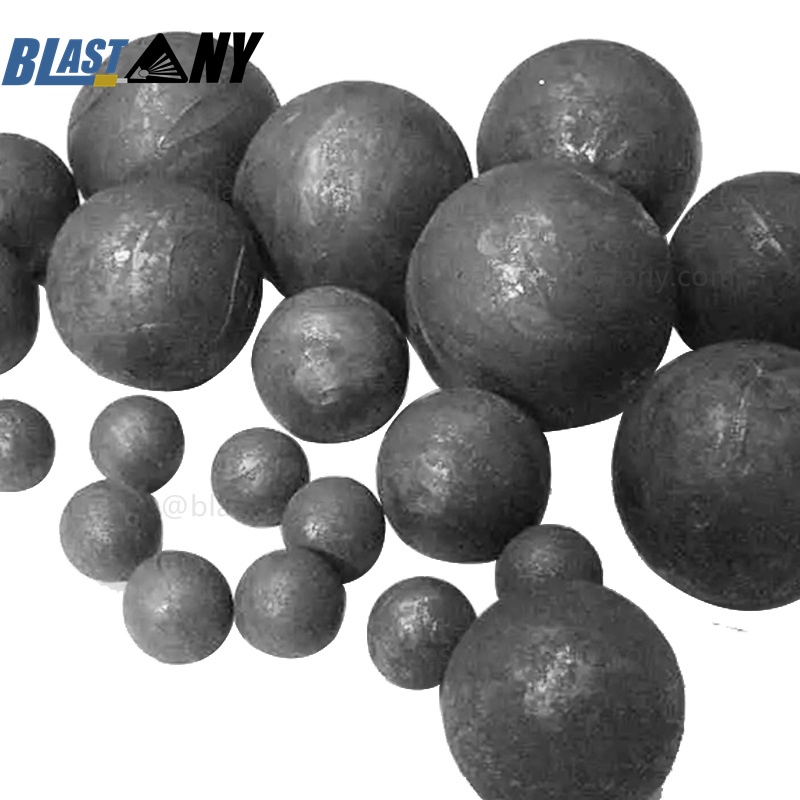

After checking and testing the round alloy steel bar material,the production can be started according to the size of the steel ball . The steel forging is heated to a certain temperature by intermediating with frequency furnace to ensure the effective generation of variables in the forging; The red-hot steel forging is sent into the air hammer and processed by skilled operators. After forging the red hot steel ball immediately into JUNDA specially designed heat treatment equipment for quenching and tempering heat treatment, the high and uniform hardness value of the steel ball can be ensured.

Feature

1.High impact toughness

2.Compact organization

3.High wear resistance

4.Low breakage rate

5.Uniform hardness

6.No deformation

Packing And Transportation

|

Container Bag |

Steel Drum |

|

| Net weight 1000kgs for all size balls | Ball size | Net Weight |

| 20-30mm | 930-1000KGS | |

| 40-60mm | 900-930KGS | |

| 70-90mm | 830-880KGS | |

| 100mm and above | 830-850KGS | |

| Bag:73×60cm, 1.5KG, 0.252CBMDrum:60×90cm, 15-20KG, 0.25CBMPallet Single:60×60×9cm, 4-6KG:Double:120×60×10cm, 12-14KG | ||

Remark

1.JD SG4-4 series is a special supporting device for JD pressure sandblasting machine.

2. Adjust the degree of tightness of outer joint can in a way adjust the spinning speed of spinning nozzle holder. And the speed should be controlled within 30~500r/min.

3.If spinning nozzle holder stops spinning or spinning too slowly, it may be because of under pressure, too tight outer joint, stuck bearings or jamed nozzle. Stop the machine, and then adjust and check.

4.Before working,pipeline in wall sandblaster should be put in the in wall from one side to another, and dry pressed air must be inlet. When working, blasting pipe should be pulled out slowly to make it get out at a constant speed. If the cleaning quality can’t meet the requirements, work again to get the satisfactory effect.

5.If the abrasives are blocked and can not be sprayed out, it should be closed down first and exhaust, then have a check. 6). Quick-wear parts should be checked regularly,they should be replaced timely if worn, or they would have a bad influence on the efficiency and the blasting quality,and maybe Exhaust bring accidents

Technical parameters

|

Technical parameters of forging steel ball |

||||||||||||

|

Inch |

Size |

T weight |

Tolerance(mm) |

Material |

Surface hardness(HRC) |

Volume hardness(HRC) |

||||||

|

3/4″ |

D20mm |

0.037+/-0.005 |

2+/-1 |

B2 |

63-66 |

63-66 |

||||||

|

1″ |

D25mm |

0.072+/-0.01 |

2+/-1 |

B2 |

63-66 |

63-66 |

||||||

|

11/4″ |

D30mm |

0.13+/-0.02 |

2+/-1 |

B2 |

63-66 |

63-66 |

||||||

|

11/2″ |

D40mm |

0.30+/-0.04 |

2+/-1 |

B2 |

62-66 |

62-66 |

||||||

|

2″ |

D50mm |

0.6+/-0.05 |

2+/-1 |

B2 |

62-65 |

61-64 |

||||||

|

21/2″ |

D60mm |

1.0+/-0.05 |

2+/-1.5 |

B2 |

62-65 |

60-62 |

||||||

|

21/2″ |

D65mm |

1.3+/-0.05 |

2+/-1.5 |

B2 |

61-64 |

60-62 |

||||||

|

21/2″ |

D65mm |

1.3+/-0.05 |

2+/-1.5 |

B3 |

61-63 |

60-62 |

||||||

|

3″ |

D75mm |

2.0+/-0.06 |

3+/-2 |

B3 |

61-63 |

60-62 |

||||||

|

3″(Hot rolled) |

D80mm |

2.0+/-0.06 |

3+/-2 |

B3 |

60-63 |

60-62 |

||||||

|

3″(Forged) |

D80mm |

2.1+/-0.06 |

3+/-2 |

B3 |

60-62 |

53-57 |

||||||

|

31/2″ |

D90mm |

3.0+/-0.07 |

3+/-2 |

B3 |

60-63 |

59-62 |

||||||

|

4″ |

D100mm |

4.1+/-0.15 |

3+/-2 |

B3 |

60-63 |

59-62 |

||||||

|

4.5″ |

D115mm |

6.3+/-0.15 |

3+/-2 |

B3 |

60-63 |

57-60 |

||||||

|

5″ |

D125mm |

8.1+/-0.3 |

3+/-2 |

B3 |

59-62 |

55-60 |

||||||

|

Chemical composition |

C% |

Si% |

Mn% |

Cr% |

P% |

S% |

Ni% |

|||||

|

B2 |

0.72-1.03 |

0.15-0.35 |

0.3-1.2 |

0.2-0.6 |

≤0.035 |

≤0.035 |

i≤0.25 |

|||||

|

B3 |

0.53-0.88 |

1.2-2.00 |

0.50-1.20 |

0.7-1.20 |

≤0.035 |

≤0.035 |

i≤0.25 |

|||||

Product detail pictures:

Related Product Guide:

Sincerity, Innovation, Rigorousness, and Efficiency will be the persistent conception of our company to the long-term to establish together with customers for mutual reciprocity and mutual gain for Hot Sale For 35mm Stainless Steel Ball - Grinding ball – Junda , The product will supply to all over the world, such as: Slovakia, Croatia, Guatemala, With top quality products, great after-sales service and warranty policy, we win trust from many overseas partner, many good feedbacks witnessed our factory's growth. With full confidence and strength, welcome customers to contact and visit us for future relationship.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!

Products categories