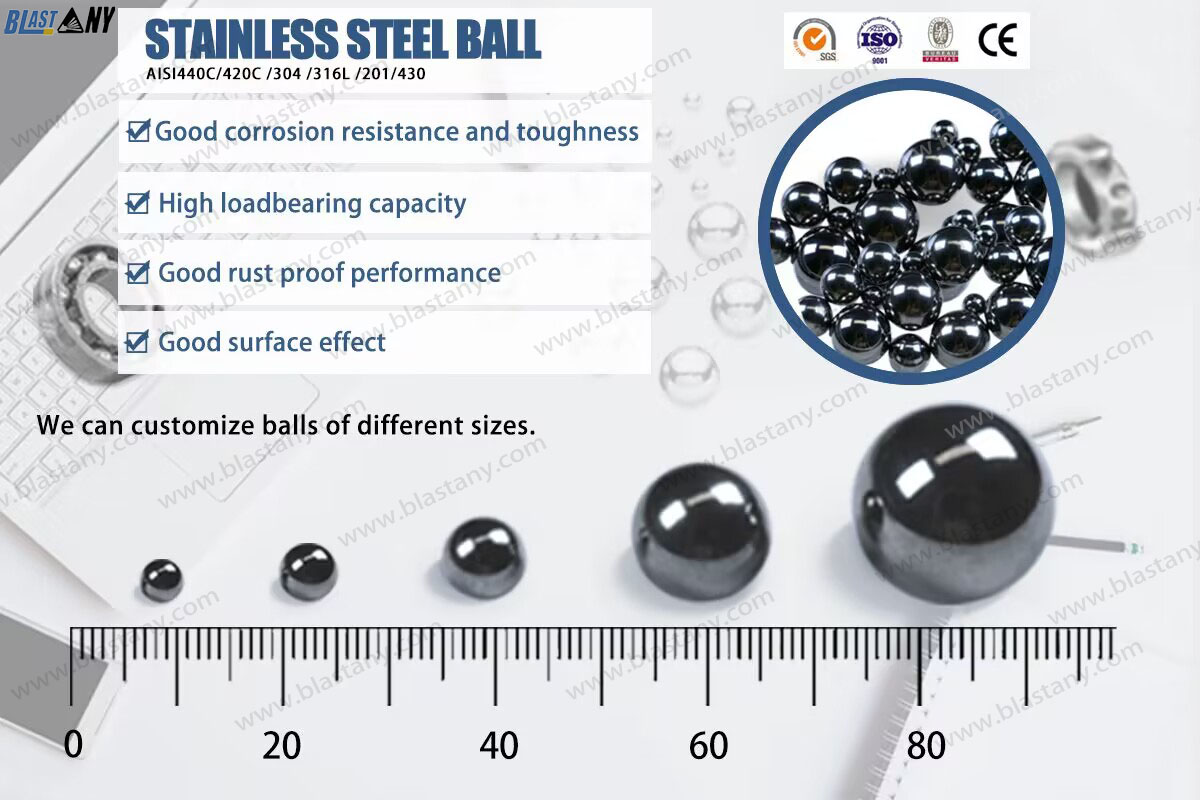

Factory supply 0.35mm- 50.8mm HRC50-55 light AISI304 316 430 440 stainless steel ball Used in Bearing

Product description

Stainless balls are capable of resisting corrosion by such agents as oxidizing solutions, most organic chemicals, food stuffs and sterilizing solutions. They are moderately resistant to sulfuric acids. Non-magnetic properties available upon request. Applications include aerosol, sprayers, finger pump mechanisms, milk machine blenders, food processing equipment and medical applications.

AISI 440C Stainless steel ball

Size: 0.35mm- 50.8mm

Grade:G10, G16, G40, G60, G100, G200.

Hardness: HRC56-58,Hartford 440C stainless steel balls are passivated to remove free iron contaminants and facilitate spontaneous formation of a protective passive film.

Magnetic:Martensitic steel, magnetic

Features: high precision, good corrosion resistance, strong rust and wear resistance.

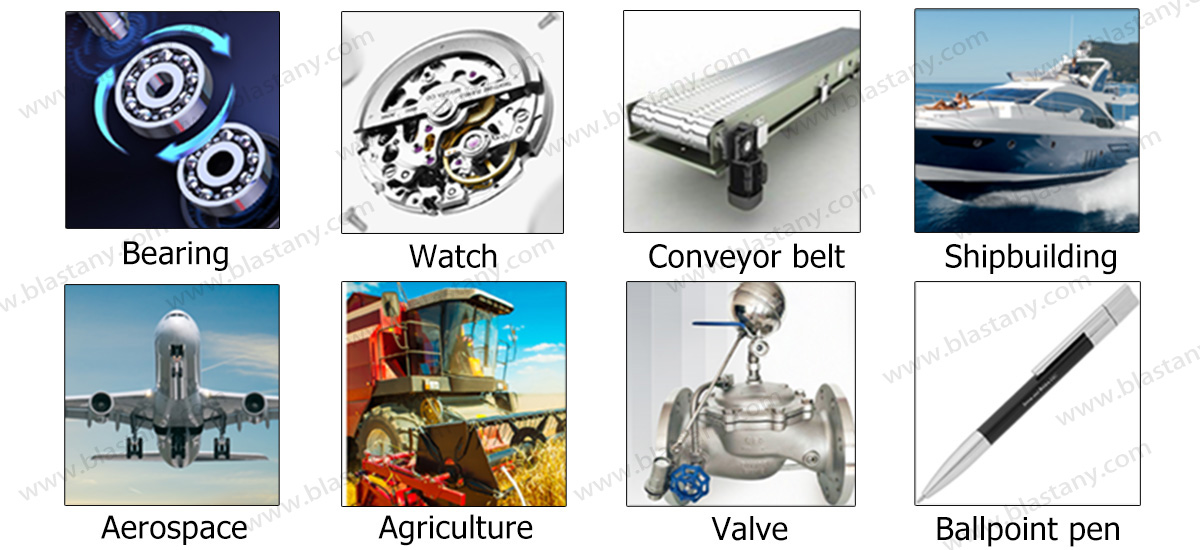

Applications:Bearings,stamping,hydraulic parts, valves, aerospace, seals, refrigeration equipment, high-precision instruments, etc.

|

Chemical composition |

||||||||

|

AISI 440C |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

|

0.95-1.10 |

≤0.80 |

≤0.80 |

≤0.04 |

≤0.03 |

≤0.60 |

16.0-18.0 |

0.75 |

|

AISI 420C Stainless steel ball

Size: 0.35mm- 50.8mm

Grade : G10-G1000

Hardness: HRC50-55

Magnetic:Martensitic steel, magnetic,Good anti-rust ability,High hardness,AISI 420 stainless steel balls demonstrate good wear characteristics and hardness. Slightly less hardness and greater corrosion resistance, when compared to 440C.

Features:Commonly known as stainless iron, good corrosion resistance and toughness.

Applications:All kinds of precision machinery, bearings, electrical equipment, household appliances, auto parts, etc.

|

AISI 420C(4Cr13) |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

|

0.36-0.43 |

≤0.80 |

≤1.25 |

≤0.035 |

≤0.03 |

≤0.60 |

12.0-14.0 |

≤0.60 |

430 stainless steel ball

Diameter: 1MM-50.80MM

Hardness: HRC26

Grade : G10-G1000

Features: low price, poor rust resistance.

Application:hardware, ornaments, accessories, cosmetics, industry, industries with low requirements for antirust performance.Cosmetics agitators, nail polish and eyeliners, heat exchangers, measurement instruments. and valve balls.

|

AISI 430 |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

|

≤0.12 |

≤1.0 |

≤1.0 |

≤0.04 |

≤0.03 |

- |

16.0-18.0 |

- |

AISI 304 Stainless steel ball

Size: 0.5mm- 63.5mm

Grade : G80-G500

Hardness: ≤HRC21

Magnetic:Austenitic steel, non-magnetic

Features: strong rust resistance, good corrosion resistance.widely used, good rust proof performance, good surface effect, environmental protection certification.

Applications:Household appliances such as valves, perfume bottles, nail polish, baby bottles, auto parts, air conditioners, electrical appliances, cosmetics, bearing slide, medical equipment, jewelry and many other industries.

|

Chemical composition |

|||||||

|

AISI 304 |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

|

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

8.0-10.5 |

18.0-22.0 |

|

AISI 316L Stainless steel ball

Size: 1.0mm- 63.5mm

Grade : G80-G500

Hardness: ≤HRC26

Magnetic:Austenitic steel, non-magnetic

Features: the most suitable for industries with high anti-corrosion requirements, and the anti-rust ability is very strong,Excellent resistance to corrosion(apart of chloridric acids),Not hardenable austenitic inox

Applications:AISI 316L stainless steel ball can be used for medical equipment, chemical industry, aviation, aerospace,plastic hardware, perfume bottle,sprayer, valves, nail polish, motor, switch,iron,washing machines, refrigerators,air conditioners,medicinal materials,auto parts, bearings, instrument, bottle.

AISI 316L Stainless steel ball

|

Chemical composition |

||||||||

|

AISI 316L |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

|

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

12.0-15.0 |

16.0-18.0 |

2.0-3.0 |

|

Product Packaging

A) Inner packing: Dry packingor oil packing are provided according to you needs.

B) Outer packing:

1)iron drum + wooden / iron pallet.

2)25kg poly bag + carton + wooden pallet or wooden box.

customized packing.

Product Parameter

| Our Stainless Steel Ball is including 440C 420C 304 316 201,The Chemical composition is as following | |||||||||

| Chemical composition(%) | C | Cr | Si | Mn | P | S | Mo | Ni | Cu |

| AISI440C SS Ball | 0.95-1.2 | 16-18 | ≤0.80 | ≤0.80 | ≤0.04 | ≤0.03 | ≤0.75 | ≤0.6 | ---- |

| AISI420C SS Ball | 0.26-0.43 | 12-14 | ≤0.80 | ≤1.25 | ≤0.035 | ≤0.03 | ≤0.6 | ≤0.6 | ---- |

| AISI304 SS Ball | ≤0.08 | 18-22 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | ---- | 8-10 | ---- |

| AISI316L SS Ball | ≤0.08 | 16-18 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 2.0-3.0 | 12-15 | ---- |

| AISI201 SS Ball | ≤0.15 | 16-18 | ≤1.0 | 5.5-7.5 | ≤0.045 | ≤0.03 | ---- | 0.35-0.55 | 1.82 |

| AISI430 SS Ball | ≤0.12 | 16-18 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | ---- | ---- | ---- |

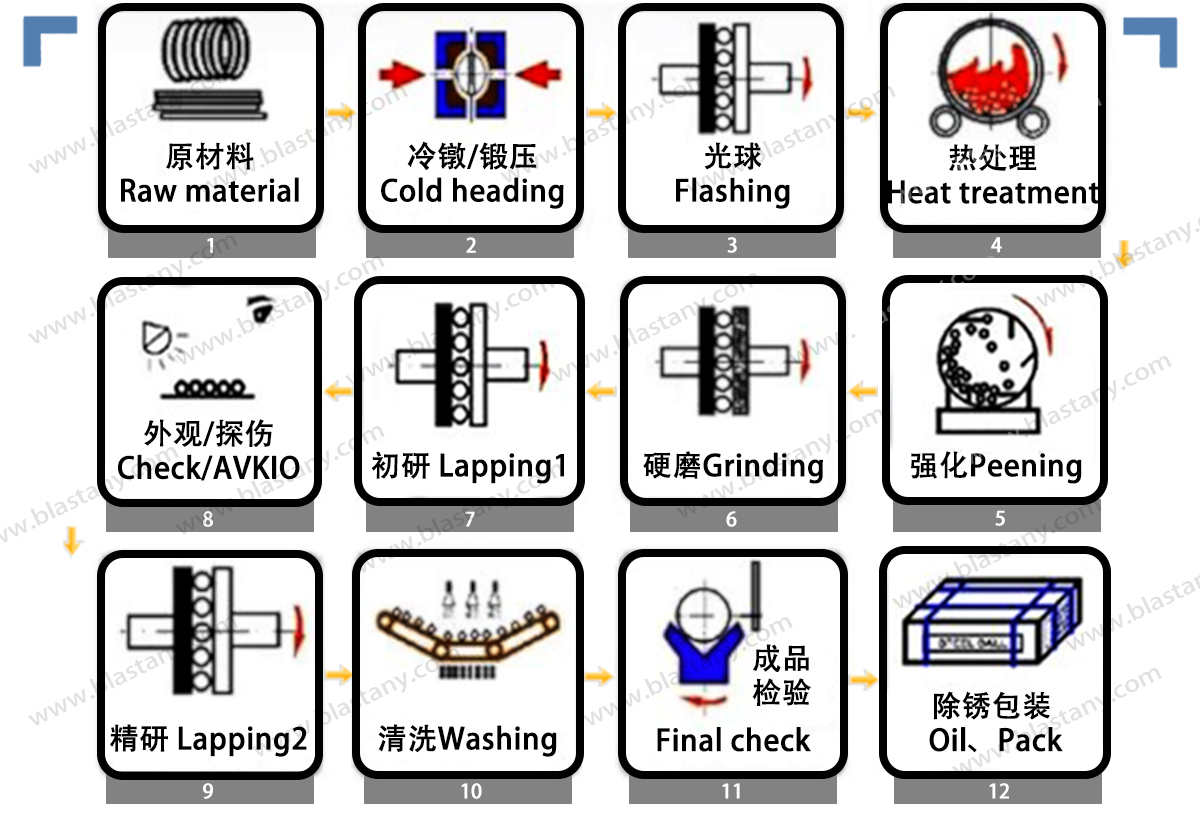

Production Flows

Raw Material Inspection

Raw material comes in wire form. Firstly, the raw material is visually inspected by quality inspectors to determine if the quality is up to the mark and if there are any defected materials. Secondly, verify the diameter and review raw material certificates.

Cold Heading

The cold heading machine cuts a specified length of the wire material into a cylindrical slugs. After that, the two hemispherical halves of the heading die form the slug into a roughly spherical shape. This forging process is performed at room temperature and a slight amount of additive material is used to ensure that the die cavity is completely filled. Cold heading is performed at very high pace, with an average velocity of one large ball per second. The smaller balls are headed at a speed of two to four balls per second.

Flashing

During this process, the excess material formed around the ball will be detached. The balls are passed a couple of times between two grooved cast iron plates removing small amount of excess material as they roll.

Heat Treatment

The parts are then supposed to be heat treated using quenching and tempering processes.A rotary furnace is used to make sure that all parts bear the same conditions. After the initial heat treatment, the parts are immersed in an oil reservoir. This rapid cooling (oil quenching) produces martensite, a steel phase which is characterized by high hardness and superior wear properties. Subsequent tempering operations further decreases internal stress until the bearings’ final specified hardness limit is reached.

Grinding

Grinding is performed both before and after heat treatment. Finish Grinding (also known as Hard Grinding) brings the ball closer to its final requirements. The grade of a precision metal ball is a measure of its overall precision; the lower the number, the more precise is the ball. Ball grade encompasses diameter tolerance, roundness (sphericity) and surface roughness also called surface finish. Precision ball manufacturing is a batch operation. Lot size is determined by the size of the machinery used for the grinding and lapping operations.

Lapping

Lapping is similar to grinding but has a significantly lower material removal rate. Lapping is done using two phenolic plates and a very fine abrasive slurry such as diamond dust. This final manufacturing process greatly improves surface roughness. Lapping is performed for the sake of high-precision or super-precision ball grades.

Cleaning

A cleaning operation then removes any processing fluids and residual abrasive material from the manufacturing process. Customers who ask for more stringent cleaning requirements, such as those in the fields of microelectronics, medical or food industries, can take advantage of Hartford Technologies more sophisticated cleaning options.

Visual Inspection

After the primary manufacturing process, each lot of precision steel balls undergoes multiple in-process quality control checks. A visual inspection is performed to check for defects such as rust or dirt.

Roller Gauging

Roller gauging is a 100% sorting process that separates both under-size and over-size precision steel balls. Please check out our separate video on the roller gauging process.

Quality Control

Each lot of precision balls is inspected to ensure grade requirements for diameter tolerance, roundness and surface roughness. During this process, other relevant characteristics such as hardness, and any visual requirements are also evaluated.

Products categories