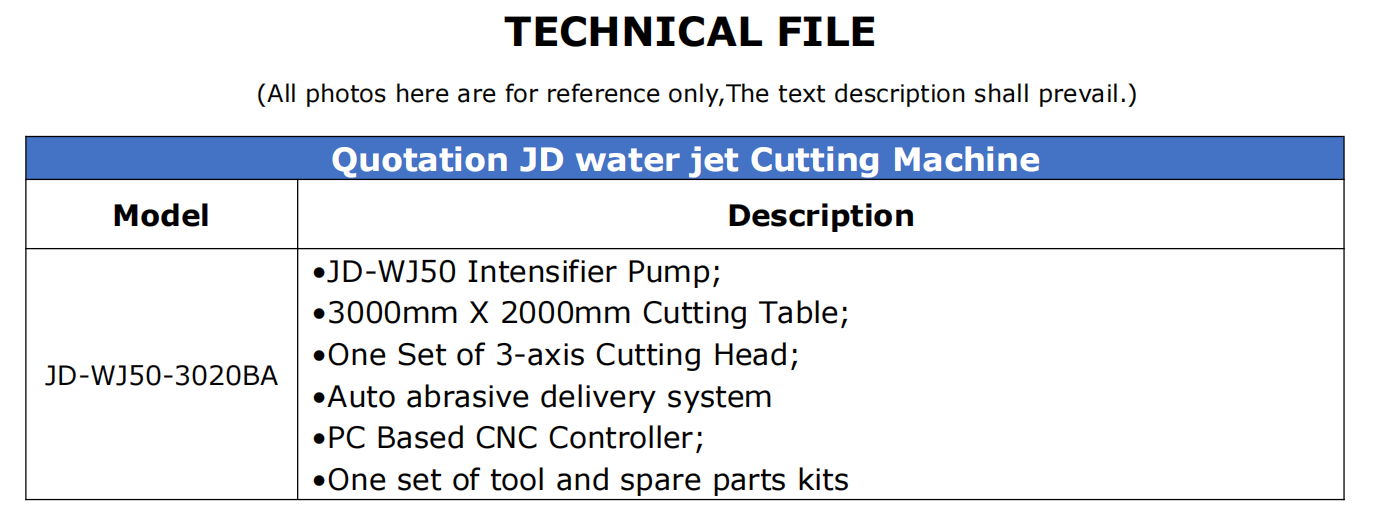

JD-WJ50-3020BA 3 axis water jet cutting machine

Product Advantages:

JD-WJ50-3020BA 3 axis water jet cutting machine

A high pressure water jet cutting machine is a tool which slices into metal and other materials, using a jet of water at high velocity and pressure. Because of its advantages of low noise, no pollution, high precision and good reliability, it has been widely used in mining, automobile, paper-making, food, art, construction and other industries.Water jet can cut almost every thing, including metal, glass,plexi glass,ceramic,marble, granite, rubber and compound material etc. Cutting accuracy:+/- 0.1mm Repeat accuracy:+/- 0.05mm

Feature

The most versatile cutting systems on the market today, covering the full range of materials and thicknesses, even painted surfaces.

Low cutting temperatures to prevent thermal alteration and residual tension.

* Clean cut without harmful atmospheres

* The cut surface neither cracks nor bends.

* Optimal utilization of raw material

* Eliminates subsequent finishing processes.

* Ability to perform different types of cutting simultaneously

* Very strict tolerances.

About Us:

Jinan JUNDA industrial technology was established in 2005.We are professional in designing, researching and developing, manufacturing and assembly, sales and technical services of water jet cutting machines.It is also a leader for the application and promotion of ultra-high pressure water jet technology.

JUNDA has established a perfect product system, mainly dealing with JUNDA cutting machine and accessories,also designing & producing customized products. JUNDA has a long-term strategic partnership with world-renowned water jet cutting manufacturers to provide the most cost-effective water jet in the industry.JUNDA water jet cutting machines are widely used in glass, metal, ceramics, stone, plastic and other industries.With reliable product ISO 9001 quality and perfect after-sales service, JUNDA company has won the trust and praise from the vast number of users.

Welcome domestic and overseas customers for business cooperation and to make efforts of the prosperity and development of water jet industry.

FAQ:

Q1:What’s the delivery time?

A : 5-10 work days after receiving client’s payment

Q2: What’s package?

A: wooden box packaging

Q3: Do you have any timely technology supports?

A: we have a professional technology supporting team for your timely services. We prepare the technical documents for you, also

you can contact us by telephone, online chat (whats, skype, phone).

Q4: What’s the payment method?

A: T/T, WESTERN UNION, MONEY GRAM,LC...

Q5: How to ensure that I received the machine undamaged?

A: At first , our package is standard for shipping, before packing, we will confirm product undamaged, otherwise, please contact

within 2days. Because we've bought insurance for you, we or shipping company will be responsible!

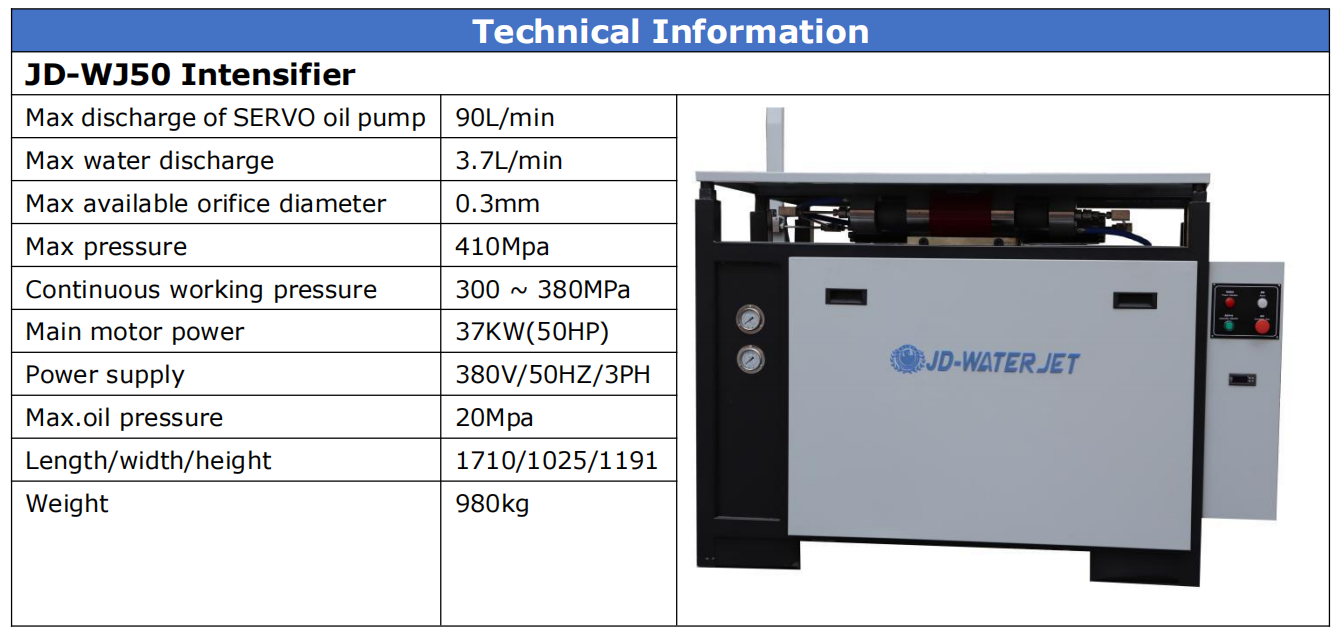

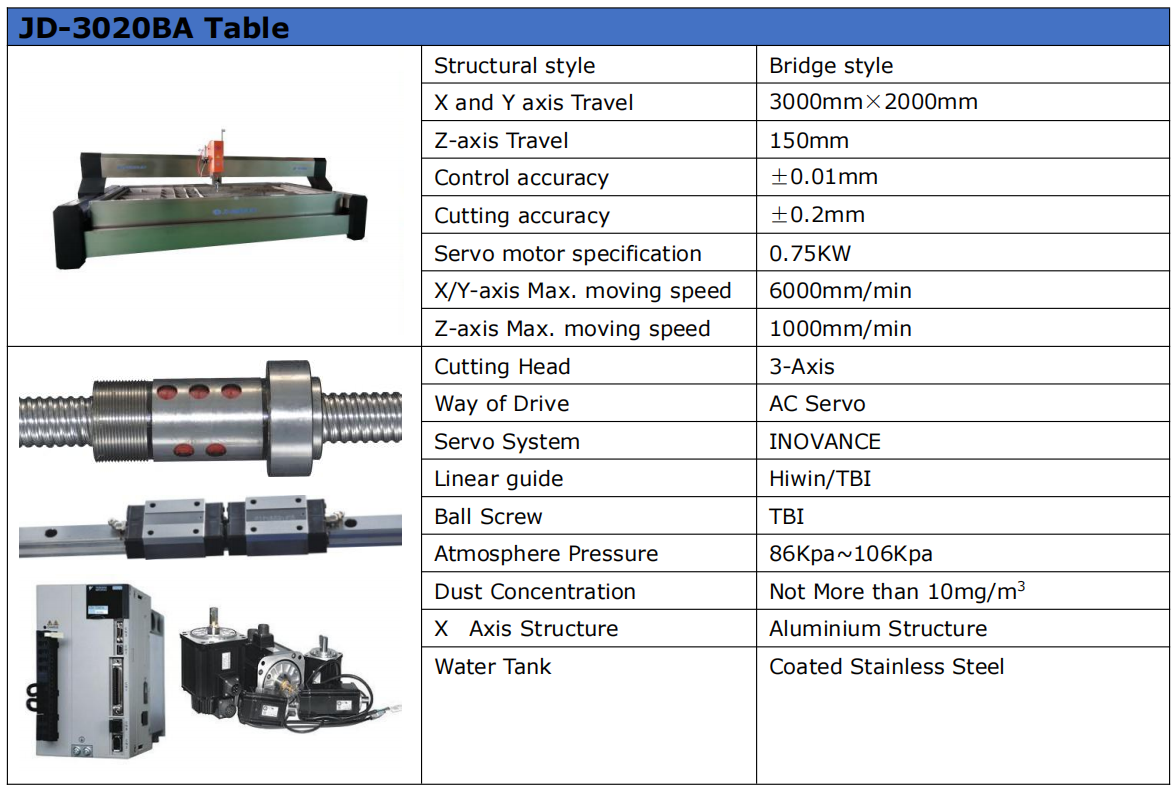

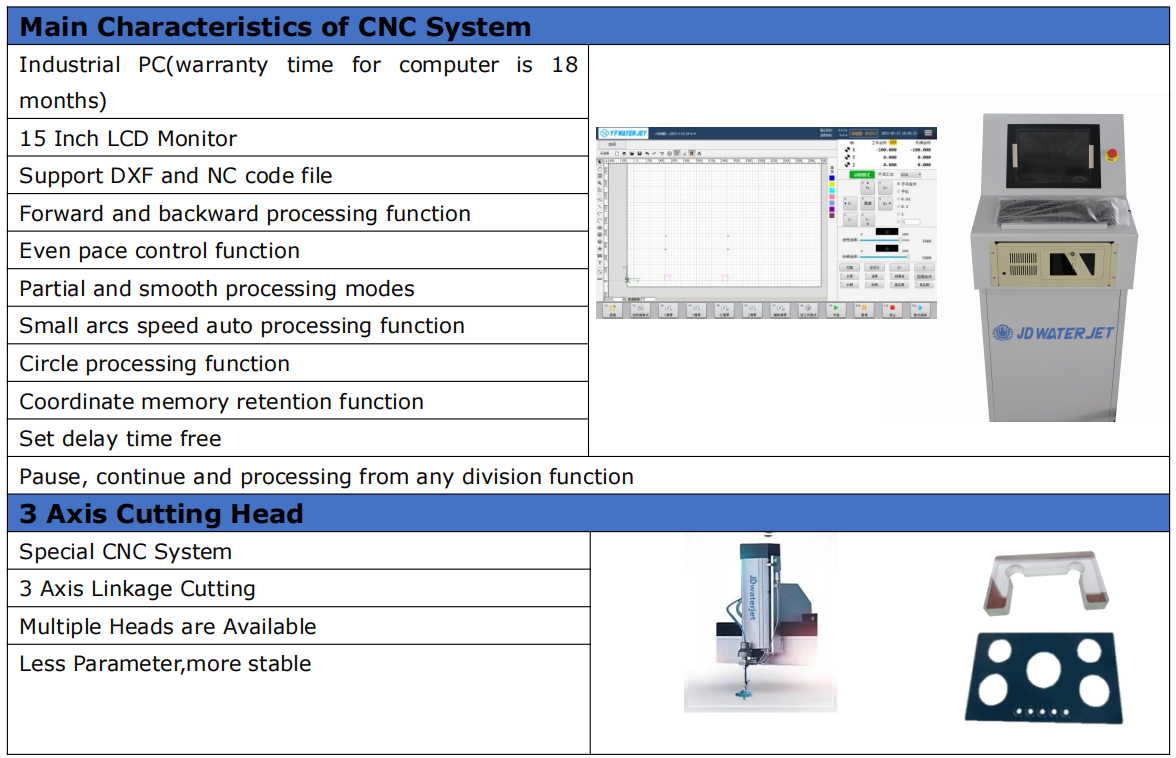

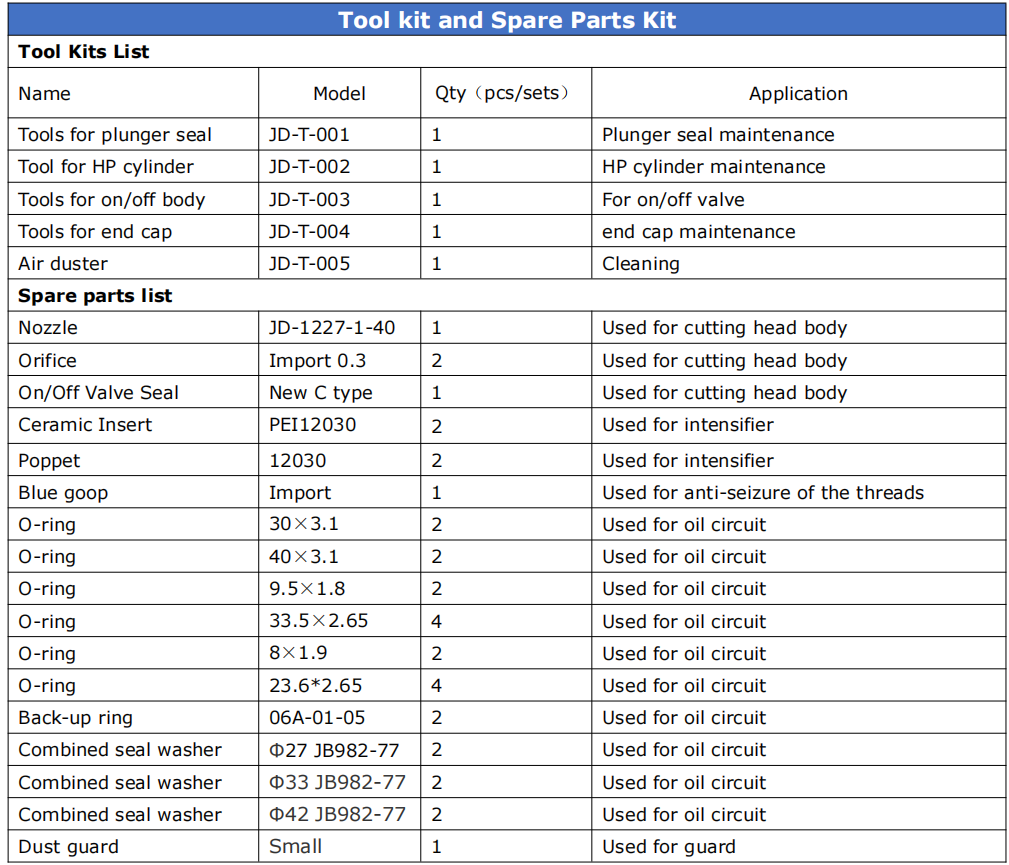

Technical parameters

|

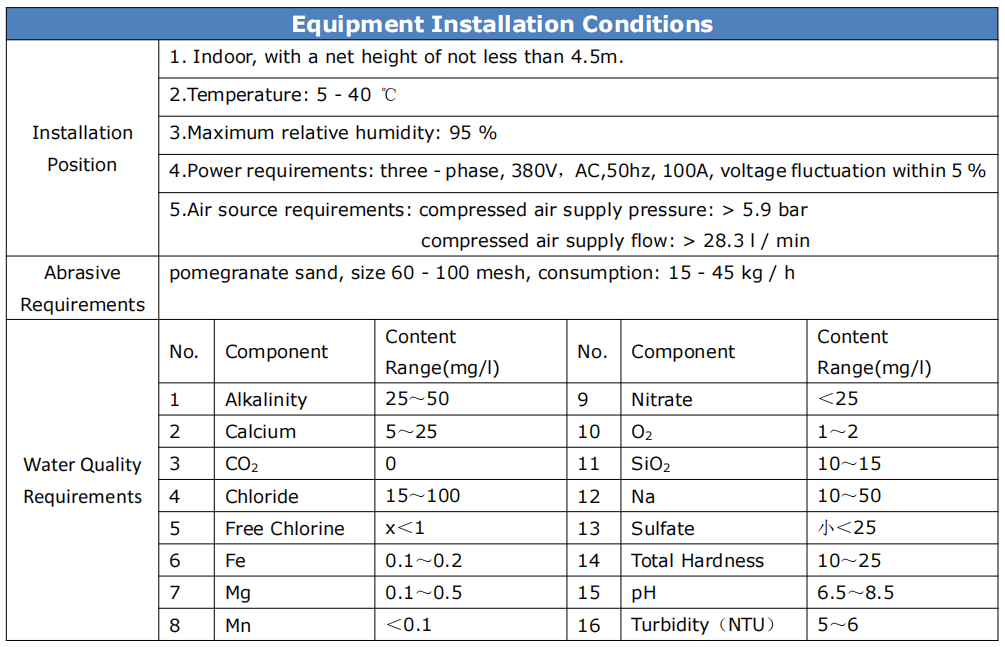

Equipment Installation Conditions |

||||||

| Installation Position | 1. Indoor, with a net height of not less than 4.5m. | |||||

| 2.Temperature: 5 - 40 ℃ | ||||||

| 3.Maximum relative humidity: 95 % | ||||||

| 4.Power requirements: three - phase, 380V,AC,50hz, 100A, voltage fluctuation within 5 % | ||||||

| 5.Air source requirements: compressed air supply pressure: > 5.9 bar compressed air supply flow: > 28.3 l / min | ||||||

| Abrasive Requirements | pomegranate sand, size 60 - 100 mesh, consumption: 15 - 45 kg / h | |||||

| Water Quality Requirements | No. | Component | Content Range(mg/l) | No. | Component | Content Range(mg/l) |

| 1 | Alkalinity | 25~50 | 9 | Nitrate | <25 | |

| 2 | Calcium | 5~25 | 10 | O2 | 1~2 | |

| 3 | CO2 | 0 | 11 | SiO2 | 10~15 | |

| 4 | Chloride | 15~100 | 12 | Na | 10~50 | |

| 5 | Free Chlorine | x<1 | 13 | Sulfate | 小<25 | |

| 6 | Fe | 0.1~0.2 | 14 | Total Hardness | 10~25 | |

| 7 | Mg | 0.1~0.5 | 15 | pH | 6.5~8.5 | |

| 8 | Mn | <0.1 | 16 | Turbidity(NTU) | 5~6 | |

| Model | JD-2015BA | JD-3020BA | JD-2040BA | JD-2060BA | JD-3040BA | JD-3080BA | JD-4030BA |

| Valid Cutting Dimension | 2000*1500mm | 3000*2000mm | 2000*4000mm | 2000*6000mm | 3000*4000mm | 3000*8000mm | 4000*3000mm |

| Cutting Degree |

0-±10° |

||||||

| Cutting Accuracy |

±0.1mm |

||||||

| Round Trip Positioning Accuracy |

±0.02mm |

||||||

| Cutting Speed |

1-300omm/min (Depending on the different materials) |

||||||

| Motor |

SIEMENS.37KW /5OHP |

||||||

| Warranty |

1 Year |

||||||

| Certificate |

CE, ISO |

||||||

| Delivery Time |

45 Days |

||||||

| After-sales Service |

Field Installation & Online Service |

||||||

| Loading Container |

FCL,20GPI40GP |

||||||

Cutting samples

Designed & manufactured to perfection, we are one of the well known and leading manufacturers and exporters of Water Jet Cutting Machinery. At our premises, we are manufacturing the cutting machinery utilizing premium quality of raw materials and components. In addition to this, the cutting machinery is best known in the market due to its remarkable features such as high performance, easy operation and durability. This Machinery finds usage in many application such as automotive, aerospace and electronics for cutting metals and non metals.

Products categories