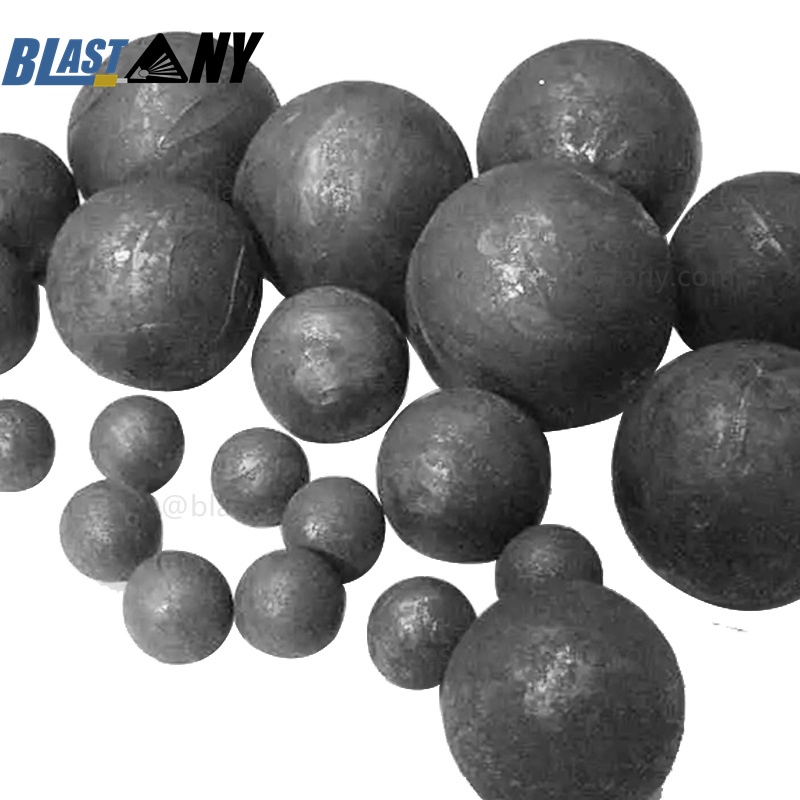

20MM TO 150MM Grinding Media Forged Steel Ball For Ball Mill

Producing process

After checking and testing the round alloy steel bar material,the production can be started according to the size of the steel ball . The steel forging is heated to a certain temperature by intermediating with frequency furnace to ensure the effective generation of variables in the forging; The red-hot steel forging is sent into the air hammer and processed by skilled operators. After forging the red hot steel ball immediately into JUNDA specially designed heat treatment equipment for quenching and tempering heat treatment, the high and uniform hardness value of the steel ball can be ensured.

Feature

1.High impact toughness

2.Compact organization

3.High wear resistance

4.Low breakage rate

5.Uniform hardness

6.No deformation

Packing And Transportation

|

Container Bag |

Steel Drum |

|

|

Net weight 1000kgs for all size balls |

Ball size | Net Weight |

| 20-30mm | 930-1000KGS | |

| 40-60mm | 900-930KGS | |

| 70-90mm | 830-880KGS | |

| 100mm and above | 830-850KGS | |

| Bag:73×60cm, 1.5KG, 0.252CBMDrum:60×90cm, 15-20KG, 0.25CBM

Pallet Single:60×60×9cm, 4-6KG:Double:120×60×10cm, 12-14KG |

||

Technical parameters

|

Technical parameters of forging steel ball |

||||||||||||

|

Inch |

Size |

T weight |

Tolerance(mm) |

Material |

Surface hardness(HRC) |

Volume hardness(HRC) |

||||||

|

3/4" |

D20mm |

0.037+/-0.005 |

2+/-1 |

B2 |

63-66 |

63-66 |

||||||

|

1" |

D25mm |

0.072+/-0.01 |

2+/-1 |

B2 |

63-66 |

63-66 |

||||||

|

11/4" |

D30mm |

0.13+/-0.02 |

2+/-1 |

B2 |

63-66 |

63-66 |

||||||

|

11/2" |

D40mm |

0.30+/-0.04 |

2+/-1 |

B2 |

62-66 |

62-66 |

||||||

|

2" |

D50mm |

0.6+/-0.05 |

2+/-1 |

B2 |

62-65 |

61-64 |

||||||

|

21/2" |

D60mm |

1.0+/-0.05 |

2+/-1.5 |

B2 |

62-65 |

60-62 |

||||||

|

3"(Hot rolled) |

D80mm |

2.0+/-0.06 |

3+/-2 |

B3 |

60-63 |

60-62 |

||||||

|

3"(Forged) |

D80mm |

2.1+/-0.06 |

3+/-2 |

B3 |

60-62 |

53-57 |

||||||

|

31/2" |

D90mm |

3.0+/-0.07 |

3+/-2 |

B3 |

60-63 |

59-62 |

||||||

|

4" |

D100mm |

4.1+/-0.15 |

3+/-2 |

B3 |

60-63 |

59-62 |

||||||

|

5" |

D125mm |

8.1+/-0.3 |

3+/-2 |

B3 |

59-62 |

55-60 |

||||||

|

Chemical composition |

C% |

Si% |

Mn% |

Cr% |

P% |

S% |

Ni% |

|||||

|

B2 |

0.72-1.03 |

0.15-0.35 |

0.3-1.2 |

0.2-0.6 |

≤0.035 |

≤0.035 |

i≤0.25 |

|||||

|

B3 |

0.53-0.88 |

1.2-2.00 |

0.50-1.20 |

0.7-1.20 |

≤0.035 |

≤0.035 |

i≤0.25 |

|||||

Products categories