Best quality Steel Grit - High hardness refractory Brown Fused Alumina – Junda

Best quality Steel Grit - High hardness refractory Brown Fused Alumina – Junda Detail:

Product Description

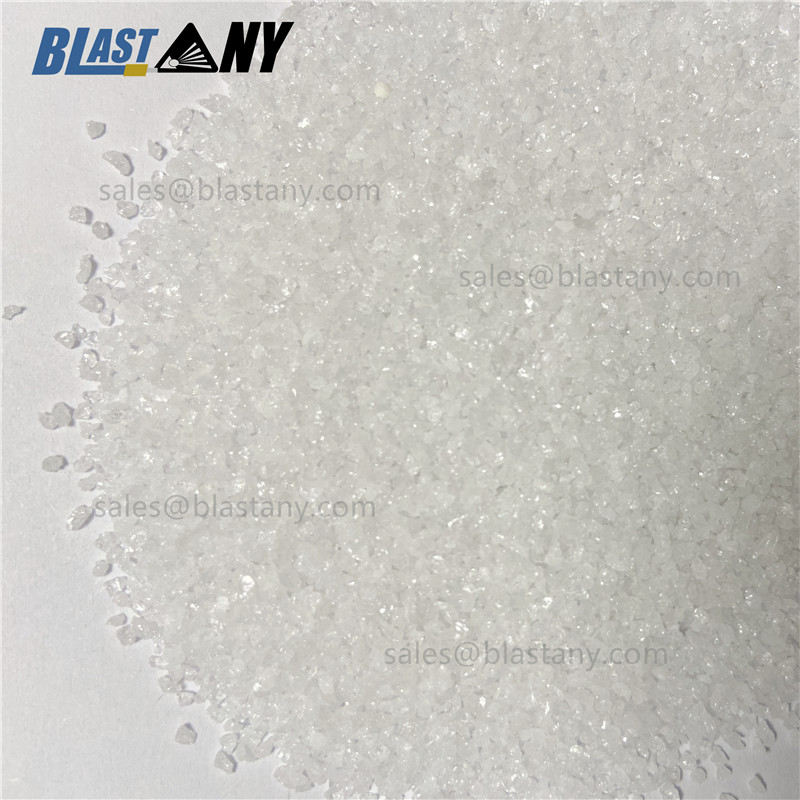

Brown fused alumina bauxite as raw material, coal, iron, high temperature above 2000 degrees hitches in arc smelting, the mill grinding plastic, magnetic separation to iron, screen is divided into a variety of particle size, dense texture, high hardness, particle formed globular, high consolidation is suitable for making ceramic, resin abrasive and grinding, polishing, sandblasting, casting, etc., can also be used for manufacturing advanced refractories.

Brown corundum its main functions:

1. Because of its high strength and other properties, it is used to cast steel sliding nozzle, smelting rare metals, special alloys, ceramics, blast furnace lining (wall and pipe); Physical and chemical ware, spark plug, heat – resistant oxidation – resistant coating.

2. Because of the characteristics of hardness, good sex, high strength, in the chemical system, used as a variety of reaction vessels and pipes, chemical pump parts; Do mechanical parts, all kinds of molds, such as wire drawing mold, squeeze pencil core mold mouth, etc.; Do tools, mold abrasives, bullet-proof materials, human joints, sealing ring and so on.

3. Corundum insulation materials, such as corundum light brick, corundum hollow ball and fiber products, used in a variety of high temperature furnace wall and top, both heat preservation. Emery particle size sand is made of artificial emery block, using roller, ball grinding, barmark and other equipment processing, particle size by F8-F325. Mainly used for polishing, grinding, industrial grinding, etc., can also be washed according to customer requirements, pickling and other processing, to meet the different needs of customers.

Low carbon brown corundum after furnace and special process of reprocessing, reduce the content of residual carbon in brown corundum, so that the product in use is not pulverized, not burst, toughness is abrasives industry, refractory industry raw materials. Mainly used for ceramic abrades, abrades, organic abrades, belts, coated abrades, etc., according to the residual carbon content is divided into: calcined brown corundum C ≤0.05%, low carbon brown corundum C ≤0.10%, ordinary brown corundum C ≤0.15%.

Technical Parameters

| Product name | Models | Leading indicator | Density | Appearance | Hardness(mohs) | Micro hardness | Melting point(ºC) | Max temperature(ºC) | Bulk density(g/cm3) | Application | Size | Abrasive Grain Sizes | ||

| Brown fused alumina | AL2O3 | Fe2O3 | SiO2 | |||||||||||

| A+ | ≥95 | ≤0.3 | ≤0.5 | 3.85g/cm3 | Brownish red particle | ≥9.0 | HV2200-2300 | 2250 | 1900 | 1.75-1.95g/cm3 | Refractory materials, fine casting | 16#-325# or According Customer Required | F12-F1200, 0-1mm, 1-3mm, 3-5mm, 5-8mm, 8-12mm | |

| A | ≥90 | ≤0.3 | ≤0.5 | Black granular gray powdery | Polish, grind | |||||||||

| B+ | ≥85 | ≤0.3 | ≤0.5 | Black granular gray powdery | Grinding, grinding wheel, cutting pieces, sandblasting | |||||||||

| B | ≥80 | ≤0.3 | ≤0.5 | Black granular gray powdery | Polish, grind | |||||||||

| C | ≥70 | ≤0.3 | ≤0.5 | Black granular gray powdery | epoxy | |||||||||

Product detail pictures:

Related Product Guide:

continue on to further improve, to make sure product top quality in line with market and consumer standard requirements. Our firm has a excellent assurance program have already been established for Best quality Steel Grit - High hardness refractory Brown Fused Alumina – Junda , The product will supply to all over the world, such as: Swaziland, Bangladesh, Liverpool, Our experience makes us important in our customer eyes. Our quality speaks itself the properties like it do not tangle, shed or breakdown, so that are our customers will always be confident while placing an order.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!

Products categories