Anthracite Coal Based 4mm Clylindrical Column Activated Carbon for Gas Treatment Coal Grain Activated Carbon Used in Industry

Columnar Activated Carbon

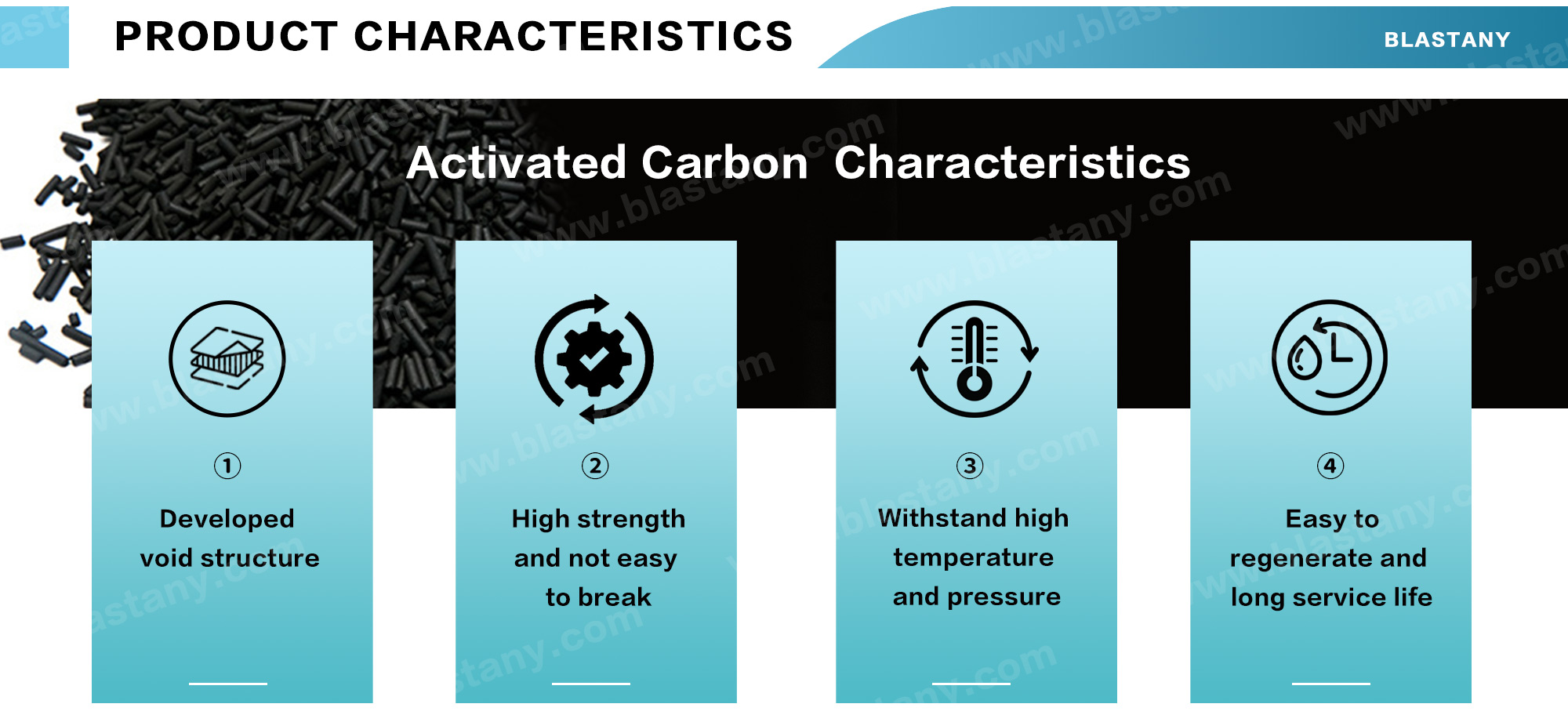

Pillar activated carbon uses high-quality anthracite coal and tar as raw materials to make columnar activated carbon. After high-temperature steam activation, a porous structure with a large specific surface area is formed. It has a well-developed structure, high strength, can withstand high temperature and high pressure, is not easily broken, is easy to regenerate, has a long life, and can adsorb a variety of organic compounds. It has multiple uses, removing contaminants such as volatile organic compounds (VOCs) and mercury from natural gas and controlling odors.

product specification

|

Particle diameter (mm) |

0.9, 1.5, 2.0, 3.0, 4.0, 6.0, 8.0 |

|

Iodine index (mg/g) |

600-1200 |

|

Apparent density (g/cm³) |

0.45-0.55 |

|

carbon tetrachloride (%) |

40-100 |

|

hardness (%) |

≥ 92 |

|

humidity (%) |

< 5 |

|

ash content (%) |

< 5 |

|

PH |

5-7 |

Coconut shell activated carbon

Manufactured by steam activation technology, It is a high performance granular activated carbon made from specially selected coconut shell based charcoal with developed pores, good adsorption performance, high strength, economic durability and other advantages. High mechanical hardness of it makes it suitable for high flow rate applications. Its high surface area ensures superior adsorption of low molecular weight organic compounds.

Description of Coconut Shell Columnar Activated Carbon Since high-quality wood chips and coconut shells are used as raw materials, the columnar activated carbon produced has lower ash content, less impurities, gas phase adsorption value and CTC than the traditional coal columnar carbon. The pore size distribution of the product is reasonable, and the maximum adsorption and desorption can be achieved, thereby greatly improving the service life of the product (average 2-3 years), which is 1.4 times that of ordinary coal-based carbon.

|

Particle diameter (mesh) |

4-8,6×12,8×16,8×30, 12×40,30×60,100,200,325 (Customized size) |

|

|

|

|

Iodine index (mg/g) |

800-1200 |

|

carbon tetrachloride(%) |

60-120 |

|

hardness (%) |

≥ 98 |

|

Apparent density (g/cm³) |

0.45-0.55 |

|

humidity (%) |

<5 |

|

ash content(%) |

<5 |

|

PH |

5-7 |

Granular activated carbon

Coal-based granular activated carbon The best choice for your project

Junda Carbon produces coal-based activated carbon products in various sizes and shapes, including granular, powdered and extruded activated carbon. Our coal-based activated carbon undergoes strict quality control from raw material selection to finished product Coal-based granular activated carbon is granular coarse activated carbon produced from the highest quality bituminous coal or anthracite coal. It is ideal for many liquid phase applications, including the removal of organic matter from waterways. Some grades are suitable for drinking water and food grade applications

Granular activated carbon applications:

Granular activated carbon is the granular form of coarse activated carbon produced from the highest quality bituminous or anthracite coal. The adsorption capacity of granular activated carbon makes it an ideal choice for removing various pollutants from water, air, liquids, and gases to improve taste, odor, and color. Typical applications of GAC include municipal and environmental water treatment, food and beverage, and metal recycling. In addition, activated carbon with different particle sizes is most suitable for steam and liquid adsorption applications. For general filtration purposes, our granular activated carbon has a mesoporous structure and will be the best choice. High physical adsorption capacity Excellent microporous and mesoporous structures.

| Particle diameter (head) | 4×8 8×16 6×12 8×30 12×40 40×60 (customized) |

| Iodine index (mg/g) | 500-1200 |

| Apparent density (g/cm³) | 0.45-0.55 |

| Methylene blue(mg/g) | 90-180 |

| hardness (%) | ≥ 90 |

| humidity (%) | ≤10 |

| ash content (%) | ≤10 |

| PH | 5-7 |

Powdered activated carbon

Powdered activated carbon is made from natural high-quality wood and high-quality anthracite coal, and is refined through carbonization and high-temperature activator processes. Lts’ unique microporous structure and huge specific surface area gives it excellent adsorption capacity and effectively remove impurities and pollutants in the liquid phase, such as organic matter, odors, heavy metals, pigments, etc. Product advantages: fast filtration speed, good adsorption performance, high decolorization rate, strong deodorization ability, and low economic cost.

Powdered activated carbon applications:

The following are some applications of powdered activated carbon:

Urban water treatment, industrial wastewater treatment, incineration flue gas purification, food processing, sugar, oil, wine, fat decolorization, decontamination, monosodium glutamate decolorization, purification, drug injection.

|

particle size (Mesh) |

100 200 325 |

|

Iodine index (mg/g) |

600-1050 |

|

Absorption value of methylene blue (mg/g) |

10-22 |

|

Iron content (%) |

<0.02 |

|

humidity (%) |

≤ 10 |

|

ash content (%) |

≤ 10-15 |

|

PH |

5-7 |

Products categories