AISI1010/1015/1085 High/Low carbon steel ball 0.8 mm – 50.8 mm Carbon steel ball for bicycle bearings chain wheel

Product description

Low Carbon Steel Ball.

| Material | AISI1010/1015 |

| Size Range | 0.8mm-50.8mm |

| Grade | G100-G1000 |

| Hardness | HRC:55-65 |

Product Description

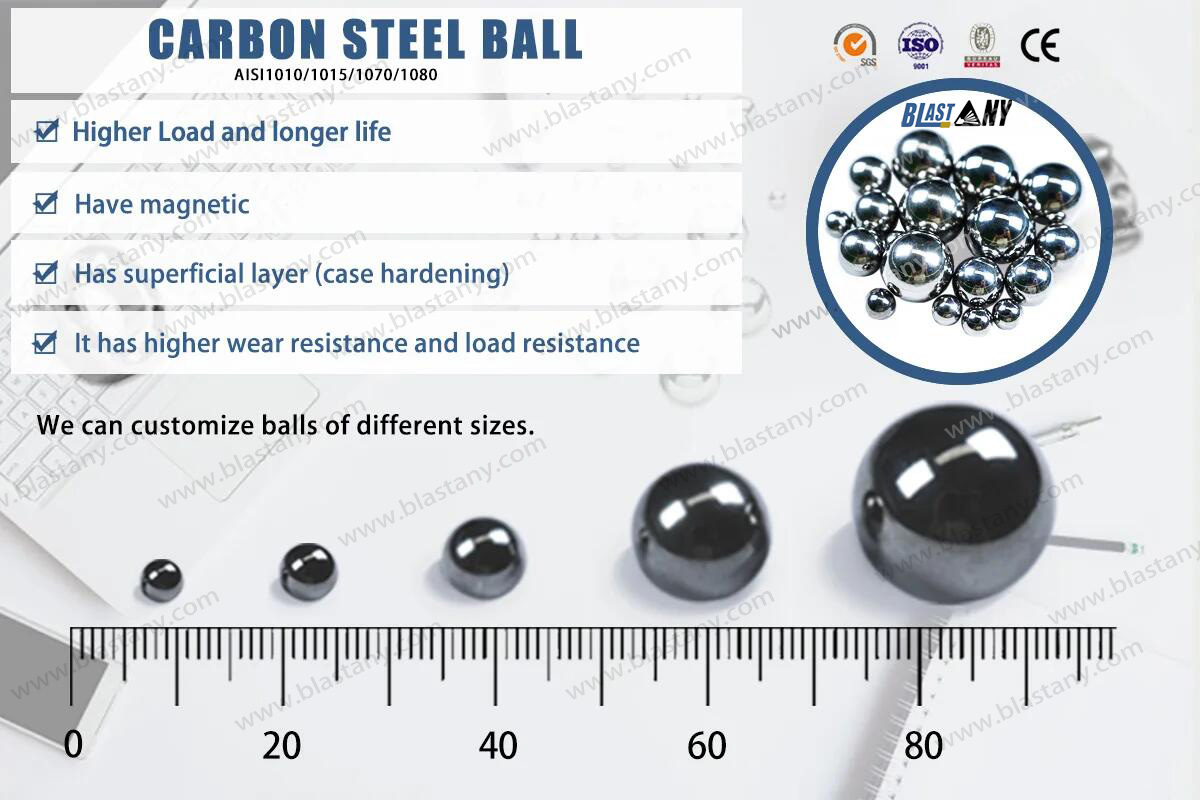

Features:

have magnetic ,Carbon Steel Balls has superficial layer (case hardening), while the internal part of the ball remains soft metallographic tructure is ferrite , package often with oil . Usually electroplating when it is out of surface , it can be plated with zinc , gold , nickel , chrome and so on . have strong anti-wear functional .Comparison : the wear-resisting and hardness is not good than bearing steel ball ( The HRC of GCr15 steel ball is 60- 66 ) : so , the life is shorter relatively .

Application:

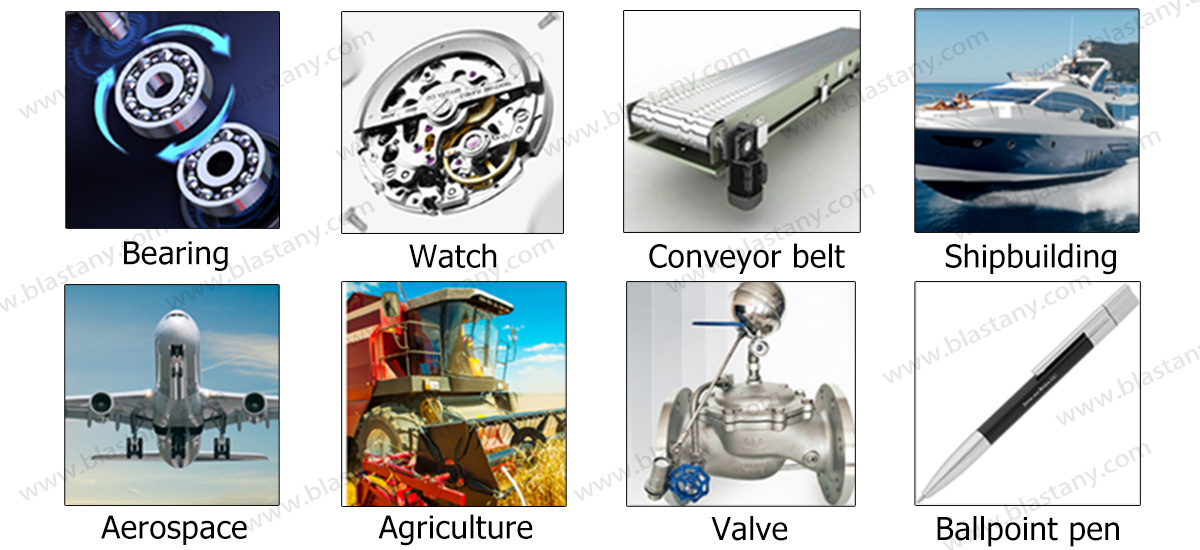

1010/1015 carbon steel ball is an ordinary steel ball,it has low price,high precision and wide use. It is used in bicycle,bearings,chain wheel, craftwork, shelf, versatile ball,bags,small hardware,it can also be used for rubbing other medium.Castors, Dressers’ Bearings, Locks, Oilers And Grease Cups, Skates.drawers Slides And Window Rolling Bearings, Toys, Belt And Roller Conveyors, Tumble Finishing.

| TYPE OF MATERIAL | C | Si | Mn | P (MAX.) | S (MAX.) |

| AISI 1010 (C10) | 0.08-0.13 | 0.10-0.35 | 0.30-0.60 | 0.04 | 0.05 |

| AISI 1015 (C15) | 0.12-0.18 | 0.10-0.35 | 0.30-0.60 | 0.04 | 0.05 |

High Carbon Steel Ball

| Material | AISI1085 |

| Size Range | 2mm-25.4mm |

| Grade | G100-G1000 |

| Hardness | HRC 50-60 |

Product Description

Features:

AISI1070/1080 Carbon Steel Balls, & High carbon steel balls has remarkable advantage in terms of whole hardness index, which is about 60/62 HRC and grants a higher wear and load resistance compared to common low carbon hardened steel balls.

(1)Core-hardened

(2)Low resistance to corrosive attack

(3)Higher Load and longer life than low carbon steel ball

Application:

Bike’s accessories, furniture ball bearings, sliding guides, conveyor belts, heavy load wheels, ball support units. Low precision bearings, bicycle & automotive components, agitators, skates, polishing and milling machines,Low precision bearings.

|

TYPE OF MATERIAL |

C |

Si |

Mn |

P (MAX.) |

S (MAX.) |

| AISI 1070 (C70) | 0.65-0.70 | 0.10-0.30 | 0.60-0.90 | 0.04 | 0.05 |

| AISI 1085 (C85) | 0.80-0.94 | 0.10-0.30 | 0.70-1.00 | 0.04 | 0.05 |

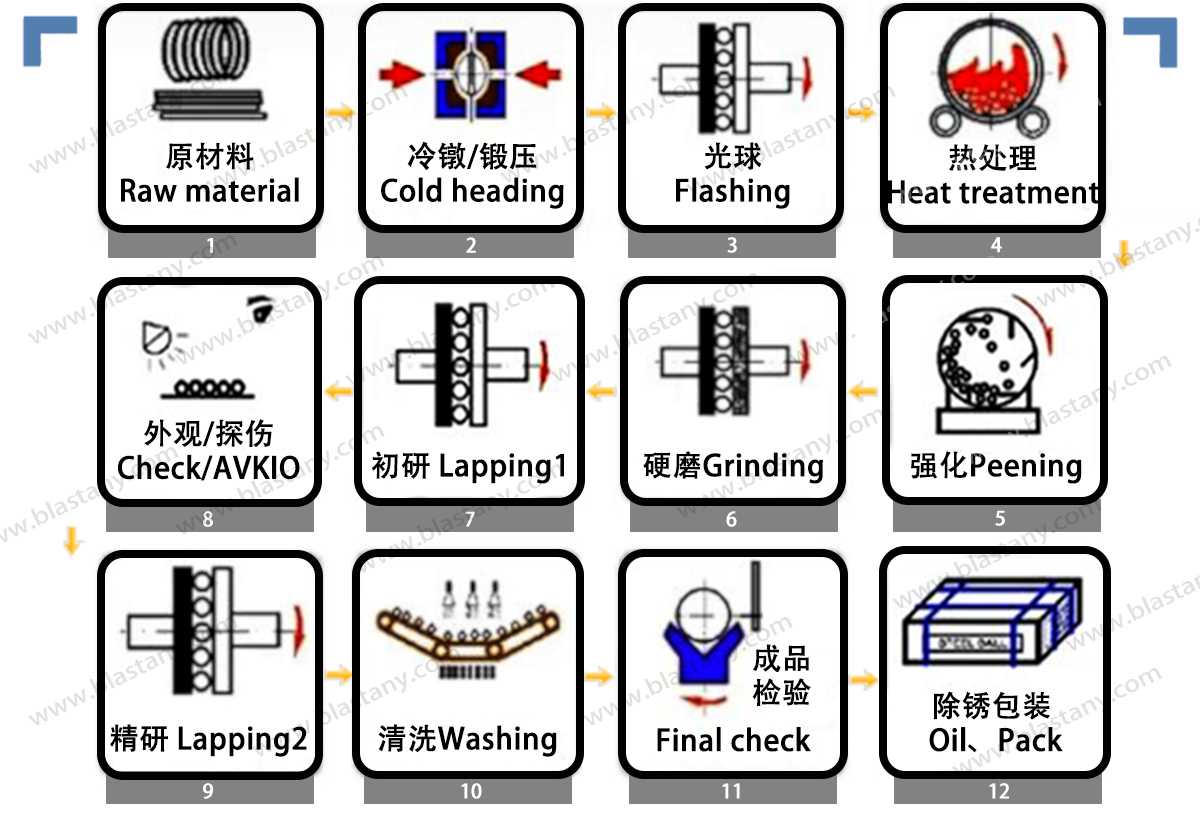

Production process

The Manufacturing Process of Precision Ball Products

1.Law Material

At its beginning stages, a ball starts in wire or rod form. Quality control goes through a metallurgic testing to ensure that the material composition is within acceptable ranges.

2.Heading

After the raw material has passed inspection, it is then fed through a high speed header. This forms very rough balls.

3.Flashing

The flashing process cleans up the headed balls so that they are somewhat smooth in appearance.

4.Heat Treatment

An extremely high temperature process where the flashed balls are placed in an industrial oven. This hardens the ball.

5.Grinding

The ball is ground to the approximate diameter of the final ball size.

6.Lapping

The lapping of the ball brings it to it's desired final dimension. This is the final forming process and gets the ball within grade tolerances.

7.Final Inspection

The ball is then precisely measured and inspected by Quality Control to ensure the highest quality.

Products categories