10MM TO 130MM Casting Grinding Media Steel Ball for Ball Mill Metal Mines and Cement Plants

Product description

Production process

A casting ball, also called a casting grinding ball, is made from scrap steel, scrap metal, and other trashed materials. The above mentioned materials are highly molten and conduct a continuous current after being heated. During the smelting stage, a large amount of metal elements such as vanadium, iron and manganese are first added to the flue gas to achieve the desired and predetermined yield. These elements can then pour the super-molten iron into a production line model of a steelmaking plant.

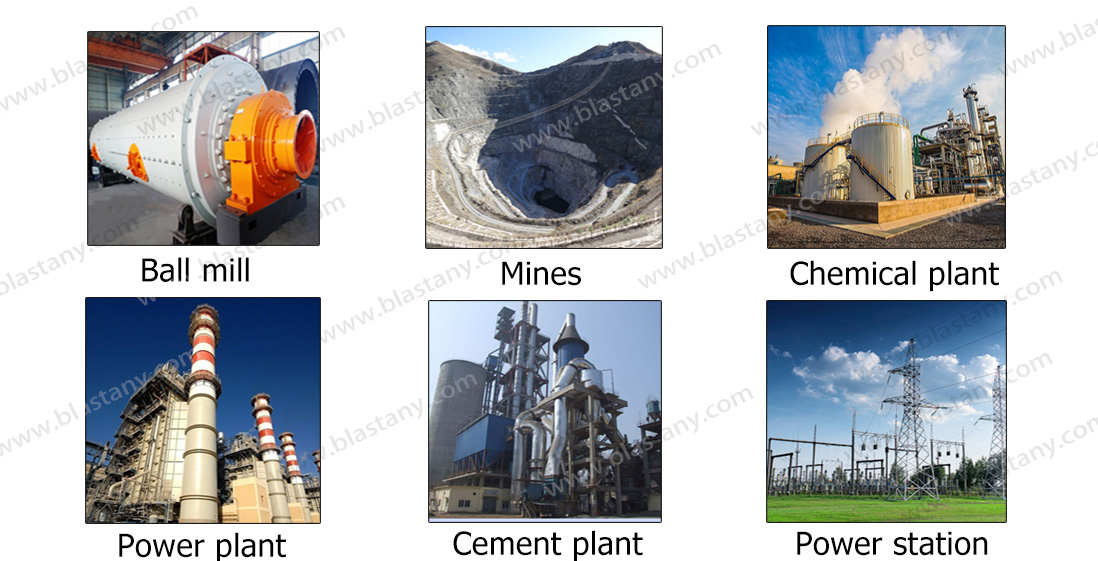

Application

Casting Steel Ball can be largely used in various applications, including

Silica sand factory/Cement plant/Chemical plant/Power plant/Mines/Power stations

/Chemical industries/Grinding mill/Ball mill/Coal mill

Introduction of casting steel ball products

Chrome cast steel balls are the cast grinding media balls containing a certain percentage of chromium, and by which are divided into high chromium cast steel balls, medium chromium cast steel balls and low chromium cast steel balls. The chromium cast steel balls are divided into High Chromium Cast Steel Balls, Medium Chromium Cast Steel Balls and Low Chromium Cast Steel Balls. With the feature of high hardness, low wear, and low breakage, cast steel grinding balls are mainly used in cement industry, mining industry, metallurgical industry, power generation industry and construction industry.

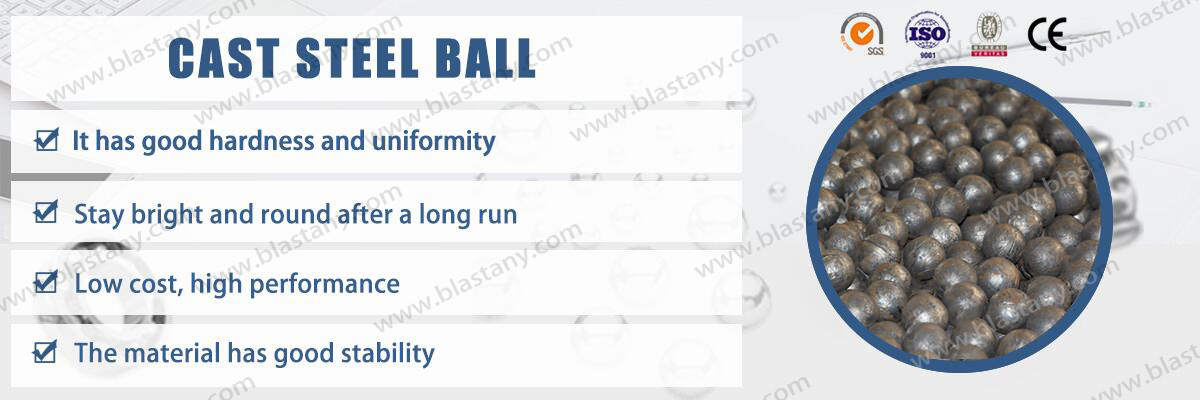

Cast Grinding Steel Ball Features

1、The raw materials are all bearing steel scraps, which contain copper, molybdenum, nickel and other precious metal elements, which can effectively improve the matrix structure of the steel ball.

2、Our products are produced by medium frequency electric furnace which can effectively ensures the stability of the material. Balls are not easy to peel off and deform during use. Even it can keep bright and round after long time running.

3、The most advanced large-scale automatic oil quenching production line is adopted for heat treatment, which ensures the good hardness and uniformity of the products.

Three methods for making steel balls

1. Three methods of steel ball manufacturing

There are three types of steel ball manufacturing processes: casting, forging, and rolling.

(1) Casting: The quality of cast steel balls mainly depends on the chromium content. In recent years, the rising price of chromium, environmental protection, and other factors have led to an increase in the cost of cast steel balls.

(2) Forging: Using high manganese steel as raw material, pneumatic forging hammers and ball molds are used to make steel balls. Forged steel balls have a reasonable combination of high-carbon, manganese, chromium, and other alloy elements, and have strong hardenability in the production heat treatment, a small difference in hardness between inside and outside, and the difference in impact value, which makes forged balls stronger than cast balls.

(3)Rolling: Using high manganese steel bars as raw materials, steel balls are made by a skew rolling mill with spiral rollers.

| Item | Chemical Composition(%) | |||||||||

| C | Si | Mn | Cr | P | S | Mo | Cu | Ni | ||

|

High chrome cast gri nding balls |

ZQCr12 |

2.0-3.0 |

0.3-1.2 |

0.2-1.0 |

11-13 |

≤0.10 |

≤0.10 |

0-1.0 |

0-1.0 |

0-1.5 |

|

ZQCr15 |

2.0-3.0 |

0.3-1.2 |

0.2-1.0 |

14-17 |

≤0.10 |

≤0.10 |

0-1.0 |

0-1.0 |

0-1.5 |

|

|

ZQCr20 |

2.0-2.8 |

0.3-1.0 |

0.2-1.0 |

18-22 |

≤0.10 |

≤0.08 |

0-2.0 |

0-1.0 |

0-1.5 |

|

|

ZQCr26 |

2.0-2.8 |

0.3-1.0 |

0.2-1.0 |

22-28 |

≤0.10 |

≤0.08 |

0-2.5 |

0-2.0 |

0-1.5 |

|

| Middle chrome cast grinding bal ls |

ZQCr7 |

2.0-3.2 |

0.3-1.5 |

0.2-1.0 |

6.0-10 |

≤0.10 |

≤0.08 |

0-1.0 |

0-0.8 |

0-1.5 |

| Low chrome cast grinding balls |

ZQCr2 |

2.0-3.6 |

0.3-1.5 |

0.2-1.0 |

1.0-3.0 |

≤0.10 |

≤0.08 |

0-1.0 |

0-0.8 |

|

High chromium casting parameters (High Chrome Ball Parameter)

| Nominal diameter | Weight of single ball in average(g) | Quantity/ MT | Surfacehardness(HRC) | Endurance impact test(Times) |

| φ15 | 13.8 | 72549 | >60 | >10000 |

| φ17 | 20.1 | 49838 | >10000 | |

| φ20 | 32.7 | 30607 | >10000 | |

| φ25 | 64 | 15671 | >10000 | |

| φ30 | 110 | 9069 | >10000 | |

| φ40 | 261 | 3826 | >10000 | |

| φ 50 | 510 | 1959 | >10000 | |

| φ60 | 882 | 1134 | >10000 | |

| φ70 | 1401 | 714 | >10000 | |

| φ80 | 2091 | 478 | >58 | >10000 |

| φ90 | 2977 | 336 | >10000 | |

| φ100 | 4084 | 245 | >8000 | |

| φ120 | 7057 | 142 | >8000 | |

| φ130 | 8740 | 115 | >8000 |

Products categories